When reading filter manufacturer's engineering data, the pressure drop is often listed at a CFM lower than what you would intend to use. Let's take a look at how you can find what the filter pressure drop will be at the higher airflow.

Higher efficiency filters can be a real blessing to individuals with allergies and respiratory problems. To them, this accessory for their HVAC system is mandatory. However, we've heard it legitimately claimed that high efficiency filters are the number one cause of poor indoor air quality (IAQ). This is because some "high efficiency" filters are so restrictive that system performance deteriorates to a point that far outweighs clean air. So what's the secret to filter selection success?

To effectively select filters that will provide adequate filtration, but not degrade the performance and efficiency of the entire HVAC system, carefully select a filter or a set of filters, with a pressure drop that will match the fan. This requires us to set a pressure budget for the filter that matches the system fan and then accurately recalculate the pressure drop of the filter at the required system airflow.

Step One: Set the Filter Pressure Budget

NCI has established recommended pressure budgets based on data collected from the performance of thousands of live systems in the field. These pressure budgets provide system design and redesign parameters when selecting air filters. Although there isn’t space in this article to review all the budget parameters, the recommended NCI filter budget for a constant speed fan is 20% of fan rated pressure, and 40% of fan rated pressure for variable speed fans.

These practical standards assure that when the system is built it will have an operating static pressure that meets the equipment specifications.

Let’s use as an example of an .80-in. rated variable speed fan. Ideally, the pressure drop over the filter matching this fan would be 40%. 40% of .80-in. equals .32-in. Let’s select a filter that has less than .32-in. of pressure drop, because the filter pressure drop will increase as the filter loads up with contaminants between cleanings.

We’ll use a high quality manufacturer provided filter system with a rated pressure drop of .22-in. However, this filter is rated for this pressure drop at 1000 CFM and the system we’re designing is a three ton system that will require 1200 CFM in cooling mode.

Will this filter pressure drop be acceptable at 1200 CFM? Or will it exceed our pressure budget of .32-in.?

Step Two: Recalculate the Filter Pressure Drop

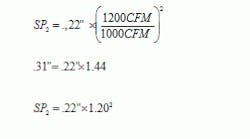

Recalculate the pressure drop of this filter using fan law two. In plain English (well, sort of plain English) this fan law teaches us that the pressure drop of a filter will increase at more than twice the rate airflow increases through the filter.

So, if the airflow through the filter increases 20%, the filter will increase more than 40%. It looks like we’ll be close.

Here’s what the math in fan law two looks like:

So the pressure drop of .22-in. over this filter at 1000 CFM jumps 44% to .31-in. at 1200 CFM. That’s quite a jump. Do you think it’s important to recalculate the increase in filter pressure drops that you select? I can recommended you make a habit of it.

With a budget of only .32-in. will this filter work? It will be close, real close. The pre-filter may need to be changed monthly in this filter system.

Expanded Filter Engineering Data

Wouldn’t it be a great idea for a filter manufacturer to offer expanded filter engineering data to help us effectively select the right filter for the job? This could be done by providing filter pressure drops at 100 CFM increments. We could then easily choose filters (or multiple filters, which is often the only way to lower high efficiency filter pressure drop enough) that would match the pressure budgets of our fans.

On the other hand, there may be some less scrupulous filter manufacturers that would be happy to keep us in the dark and keep flogging truckloads of filters to whomever they can.

Imagine the millions of dollars per year it would save equipment manufacturers and consumers in compressor and heat exchanger warranty expense if manufacturers would provide filter pressure budgets and then ask for documentation of system static pressures with each warranty claim. Now that would be an industry paradigm shift! Does that mean some manufacturers would rather pay the warranty claim than take time to teach correct principles? That’s an interesting question.

Next time you select a filter consider the appropriate filter pressure budget and then recalculate the filter pressure drop to match the maximum airflow the system is required to deliver. Go ahead, build a better system and measure how well it performs.

Rob “Doc” Falke serves the industry as president of National Comfort Institute a training company with technical and business level membership organizations. If you're an HVAC contractor or technician interested in a free Filter Recalculating Procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles and downloads.