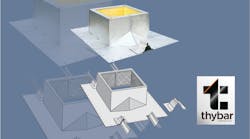

Roof installations of heating, ventilating and air conditioning units is made easier with equipment mounting supports from Thybar Corporation, Addison, Ill. The supports have a high load bearing capacity attained by a system of internal bulkheads welded into position at specific intervals along the lengths of the rails.

Three basic styles of supports are offered; TEMS-1, TEMS-2, and TEMS-3. Standard construction includes: welded 18 Ga. Galvanized steel shell, base plate and counter-flashing, factory installed wood nailer, fully mitered end sections (Models TEMS-2 & TEMS-2) and internal bulkhead reinforcement. Optional features are: additional height, heavier gauge metal, construction to fit roof pitches, wood nailers up to 2” x 12”, pressure treated wood nailers, and overhanging wood nailers.

Supports for special applications include: roller supports complete with painted roller, 18-in. threaded rods, nuts & spring nuts. The support has a continuous wood nailer covered by a removable counter-flashing.

For further information, contact: Thybar Corporation, 913 South Kay Avenue, Addison, IL 60101.

Contact by phone: 800-666-CURB. E-mail: [email protected] Website: thybar.com.