Now that we're in the midst of the R-22 phase-out, over time the need to retrofit R-22 systems is sure to arise. Exactly when that will happen remains the subject of debate and speculation, and will not be addressed here. However, for those who wish to be proactive, here are some retrofit pointers:

Buyer Beware

The term "drop-in" implies that for retrofits all you have to do is "drop in" the new product and the system will work as if nothing has changed. This is not so. No two refrigerants behave the same way. There will be performance differences. The use of so-called drop-ins also has led people to skip routine practices, such as changing filter-driers, setting superheat, or even recovering the original refrigerant.

Many Choices

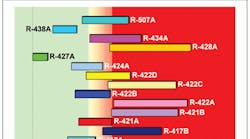

There are 18 ASHRAE designated products that can be considered R-22 retrofits in North America (see Table 1). Because sifting through these products can be tedious, here are some tips to simplify things:

- All R-22 retrofits are based on two or more of the four basic HFCs (R-32, R-125, R-143a, and R-134a). Learn how each of these components works, and you’ll be ahead of the game.

- Many R-22 retrofits contain additives—hydrocarbons (HCs) or lubricants used to improve mineral oil (MO)/alkylbenzene (AB) solubility.

- Many of these blends are similar. If you're disappointed by a particular retrofit, odds are similar products won't fare much better. Finally, bear in mind that while retrofits can help extend system life, they'll not fix existing problems, such as poor oil circulation. Be sure to resolve these issues before you retrofit.

Mixed Drinks

All of these retrofits are blends (400 or 500 series ASHRAE numbers) and should be charged as liquid. Most are high glide blends, susceptible to fractionation from leaks. While many leaks won't significantly alter blend composition, slow vapor leaks on dormant systems may require special attention. Also, high glide blends are not recommended for flooded evaporator retrofits.

Where the Rubber Meets the Road

Why are many systems retrofitted? Because of leaks. What can you get when you retrofit an old R-22 system? More leaks. Sadly, HFCs don’t expand elastomers the same as R-22 does, which can create "retrofit-induced" leaks. At a minimum, replace all Schrader valve caps/cores, and other critical seals before the retrofit. Leak-check O-ring joints afterwards.

Striking Oil

All R-22 retrofits are primarily HFCs that typically use polyolester (POE) oils, as they are immiscible with mineral oil (MO) or alkylbenzene (AB). However, twelve R-22 retrofits are positioned as NORs (no oil-change refrigerants) based on small amounts of HC/lubricant additives. While NORs can work with MO or AB in some systems (as can pure HFCs), they still are immiscible and may struggle with oil return and/or oil logging. This can lead to inadequate compressor lubrication or reduced system performance. Good piping practices and proper use of POE with an R-22 retrofit is the best way to ensure oil return and optimize performance.

Go with the Flow

Many R-22 retrofits require significantly higher mass flow to provide the same cooling capacity and avoid starving the system (see red zone in Figure 1). This may lead to replacement of components, such as expansion devices, distributor nozzles, or even line-sets, when using these products. Retrofits with similar flow rates (i.e. R-407A) typically do not require thermal expansion valve replacement. However, adjustments are required, and an assessment of other system components is still recommended.

Finding Your Niche

Knowing where to use an R-22 retrofit is critical (see Table 2). Lower pressure refrigerants are noticeably lower in capacity, and are often used in higher temperature systems.

Similar pressure products tend to have wider application but are still lower capacity than R-22, particularly in refrigeration. Most higher pressure retrofits are refrigeration only, and have closer capacities. A careful evaluation of system loading is essential because all R-22 retrofits produce changes in system capacity, particularly at higher ambients. Longer run times are a common retrofit side effect. While this may be acceptable for some units, capacity-critical systems may fail to meet load requirements after a retrofit.

Know the Issues

When it comes to retrofitting R-22, there are no easy answers or, in our opinion, "drop-in replacements." However, understanding the issues and limitations will be essential to providing quality service for our industry in the years to come.

Stephen Spletzer is senior technical sales engineer for the Arkema Inc. North American Fluorochemicals business. He can be reached at 610/8978-6953.

Gus Rolotti is technical marketing director for the Arkema Inc. North American Fluorochemicals business. He can be reached at 610/878-6953.