My second-grade granddaughter, Taylor, asked me to answer a tough homework question last night. She asked, "What am I? I am a gas; I smell like nothing; I am everywhere; You can't see me, and people like me." Taylor was impressed when I answered, "I am the air." Little did she know my passionate interest in the subject of air.

Let's take a closer look at the fascinating properties of air from an HVAC perspective.

What's in Air?

Several people answered Taylor's question with "Oxygen." She suspected that was the wrong answer and was delighted when she learned why.

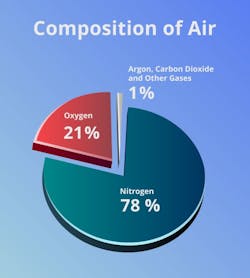

Air is made up of 21% oxygen, 78% nitrogen, and around 1% of other gasses. I was pleased to report how Mother Earth maintains these percentages all around the world. She thought that was cool, and so do I.

Of course, depending on your current location and activity, other substances, like pleasant scents, easily drift through the air. Throughout a typical day, you may also encounter undesirable elements in the air.

Most important, we can only live about three minutes without air. This fact fascinated my granddaughter. It was something she had not previously thought about.

Standard Air

Air properties are constantly changing. They depend on temperature, altitude, and humidity. Standard air is the baseline and defined as dry air at 70 degrees Fahrenheit, at sea level.

Most HVAC formulas use standard air as their foundation. So when you measure or calculate air under conditions much different than this standard, you'll want to adjust the air properties of the formula to assure accurate results.

Air takes up space. It consists of atoms and molecules. One pound of 70-degree air fills a 29-in. x 29-in. x 29-in. cube at sea level.

Air is HeavyNext time you drive down the road, open the window and stick your arm out, and cup your hand facing into the wind. You'll feel the force of the air pushing against your hand and arm. The faster you drive, the more air hits your arm. Air IS heavy. Let's calculate how heavy. One cubic foot of air weighs .075 pounds or about the weight of a pencil. The area of your hand and arm facing the wind is about one square foot. If you're moving at 35 miles per hour, that speed converts to .58

miles per minute or 3062 feet per minute.

Multiply 3062 feet per minute by .075 pounds to find 230 pounds of air is hitting your hand and arm per minute. Yes, the air is heavy.

To get a better picture of the weight of air, consider the amount of air a fan moves in an hour. Thirty pounds of air per minute per ton equals 1800 pounds an hour. (400 cfm = 30 pounds x 60 minutes per hour = 1,800 pounds) That's almost one ton of air to move one ton of cooling per hour!

An air conditioning system should move about 400 cubic feet of air per minute (cfm) per ton of cooling. Four hundred cubic feet of air weighs 30 pounds (400 x .075 pounds = 30 pounds)

To get a better picture of the weight of air, consider the amount of air a fan moves in an hour. Thirty pounds of air per minute per ton equals 1800 pounds an hour. (400 cfm = 30 pounds x 60 minutes per hour = 1,800 pounds) That's almost one ton of air to move one ton of cooling per hour!

This fact provides added insight when diagnosing restrictive air filters, coils, or duct systems. Imagine the resistance to airflow caused by trying to pull nearly 10,000 pounds of air per hour through a high-efficiency air filter in a five-ton system.

Altitude Affects Air Density

At higher altitudes, air density decreases, or it gets thinner. I used this excuse to slow down after a couple of hours of trying to keep up with Taylor and her family as we played on the beach, hiked, and climbed rocks at Lake Tahoe (Elevation over 6000 feet).

When designing or testing HVAC systems at higher elevations, you must make adjustments to compensate for lower air density at higher elevations.

Changes in air density are easily understood as you examine airflow required at different elevations. At sea level, most cooling systems require 400 cfm per ton. Cooling systems at 5,000 feet above sea level require airflow of 465 cfm per ton. A system operating at 10,000 feet needs 580 cfm per ton.

As altitude increases, each cubic foot of air contains less mass or has less stuff in it. Heating equipment adds heat to the air, essentially transferred from the heat exchanger into the stuff in the air. To get the same amount of stuff at higher elevations requires more airflow.

Temperature Affects Air

Hot air rises. Just as air density decreases at higher altitudes, air density and the weight of air decrease when heated. Hot air balloons are an excellent example of this principle. The lighter air weight inside the balloon compared to the air outside the balloon causes it to rise.

Air density changes as air passes through a heating system. For example, if air enters a system at 70-degrees, and leaves the system at 135-degrees, the air is 10% less dense when it leaves than when entering the system.

In a cooling system, air may enter at 75-degrees and leave at 55-degrees. The air is denser as it leaves the indoor coil.

Supply register engineering data confirms 55-degree air is almost 15% heavier than 135° air. A supply register will throw air 15% farther in heating mode than in cooling mode.

Hot Moves to Cold, Warm Air Rises, and Cool Air Falls

As contractors, your job involves transferring air and heat from one place to another to make homes and buildings more comfortable. To do this, you harness the second law of thermodynamics which teaches hot moves to cold.

A gas furnace burns fuel. The burning fuel produces heat. Hot air rises as cooler air falls. Decades ago, we used gravity furnaces to heat homes where heat rose through large ducts from a furnace in the basement. We used no fans.

In the cooling cycle, heat in the air is attracted to the cool refrigerant in the coil. Heat is carried out to the condensing unit and discharged outdoors.

Today, most systems use a mechanical fan to mix cooler air with warmer air and propel it into each room to create even temperatures throughout the home.

In the cooling cycle, heat in the air is attracted to the cool refrigerant in the coil. Heat is carried out to the condensing unit and discharged outdoors.

The laws of heat transfer operate all around us, whether or not we're aware of them. If you are in a warmer climate, consider the hot air you breathed out yesterday while inside a building. Your hot breath moved through the building by a fan, over the indoor coil, into the refrigerant, and discharged from the condensing unit outdoors. The wind then moved the heat from your breath, perhaps northeast at 10 miles each hour. Today, the heat from your breath is 240 miles northeast from where you breathed it out.

Air properties produce fascinating results, don't they?

Tip of the Iceberg

This short article, prompted by a second grader's homework question, only touched on several of the many air properties we use to harness and control air. Perhaps in another article, we can look at how high pressure moves to low pressure. We can also address what determines the rate heat moves from hot to cold and provide several helpful calculations to predict changes in air properties.

Your opportunity is to continue learning, observing, and controlling air properties to serve your customer better and expand your career.

Rob "Doc" Falke serves the industry as president of National Comfort Institute, Inc., an HVAC-based training company and membership organization. If you're an HVAC professional interested in a free altitude and temperature air density correction table, contact Doc at ncilink.com/ContactMe or call him at 800-633-7058. Go to NCI's website at nationalcomfortinstitute.com for free information, articles, downloads, and current training opportunities