Supermarket refrigerated display cases typically rely on the process of convection to transfer heat out of them and to keep the products they display cold. These types of cases work by circulating cooled air through the case. As the cooled air flows over the product, the difference in temperature between the air and the product causes heat to move from the (relatively) warmer product to the cooler air. Most convection-cooled display cases accomplish this heat transfer in one of two ways. In the most common way, fans drive the circulated air. This method is called forced-convection.

Another approach relies on the natural tendency of cold air to sink and warm air to rise. A particular type of evaporator called a gravity coil is mounted at the top of the case instead of at the bottom as in of forced-air cases. This latter approach is referred to as natural convection.

Either way the process is the same; cooled air flowing over the product removes heat to maintain the product at the desired temperature.

Even though convection heat transfer has been used to refrigerate perishable products for decades and remains the most widely used method throughout the industry, forcing air over unpackaged products has certain significant drawbacks.

Air, it turns out, is not necessarily a good conductor of heat. In fact, dry air is actually a very good insulator. That might seem counter intuitive since air circulation is so widely used in so many different approaches to heating and cooling. But, to take one example found in many homes, the air between the two panes of glass in a thermal pane window provides the insulating capability of the window. Without the air between them, the two panes of the window would be hardly anymore effective than its single pane counterpart. Fiberglass insulation in the walls of the home also works in a similar way to trap dry air and retain heat.

So one might wonder at this point that if air is such a good insulator, why is it the standard cooling medium in so many refrigerated display cases?

For one thing, air is available everywhere, it’s free, it’s extremely easy to use, and it doesn’t require any special preparation or handling. For most display cases, fans are all that are needed to move the air. And on those cases that use natural circulation gravity coils, fans aren’t even needed since the air moves by itself. For another, even though air is not the best conductor of heat, it still conducts to some extent. So for many, its availability, ease of use, and low-cost outweigh its meager heat conducting properties.

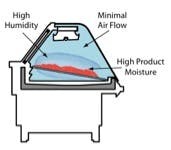

But given its heat conducting characteristics, using air as a cooling medium brings with it certain compromises. The effectiveness of convection cooling depends on how cold the air is and how much of it flows over the product. To increase the cooling, the air can either be made colder or the airflow rate can be increased. For example, a typical forced-air circulation meat case may use air at approximately 28F. But in order to maintain the product at that temperature, a lot of air has to flow over it. As the volume of air flowing over the product increases, so too does evaporation from the surface of the product. Evaporated moisture from the product is carried away as water vapor to the coil where it freezes and forms frost. Moisture that helped to maintain freshness and case humidity gets frozen on the coil. When

the case goes into defrost, the frost melts and drips to the bottom of the case and down the drain. With a product such as fresh meat that is sold by the pound, the loss of water weight means a lower selling price. And if that’s not enough, high flow rates of air also have the additional side effect of cooling the surfaces of the case to the point where condensation on them is produced.

The question for the retailer then is how best to cool the product while preserving freshness, maintaining sales weight, and wasting as little energy as possible. Until the advent of some key developments, the industry had been unable to adequately answer those questions while still relying on convection heat transfer. Another approach was needed.

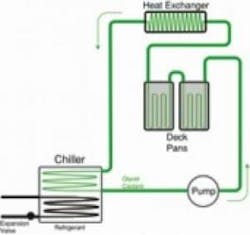

Besides convention, heat can be transferred in two other ways: radiation and conduction. An incandescent light bulb radiates heat along with the light it produces. But the other way that heat can be transferred is the basis for a relatively new approach to display case cooling. When heat is transfer through the direct physical contact of two objects (or surfaces) at different temperatures, it’s called conduction. Heat flows between two any objects that are in contact with one another, from the warmer surface of one to the cooler surface of the other until both reach the same temperature, or equilibrium. In a display case designed to use conduction, the bottom of display area is made up of a special type of deck-pan through which a chilled fluid flows that cools the deck pans to a desired temperature. The deck-pans in this arrangement work as fully flooded heat transfer surfaces that 100% cooling efficiency. Product placed on the deck-pans is directly cooled to the desired temperature by contact with the deck-pans. And since there is

no air flowing over the product to cool it, there is very little moisture lost from evaporation.

But the success of this approach relies on more than just a cold surface. The temperature of the deck-pans is not kept constant. Instead, the flow of coolant through them is constantly cycled between a low set point of 29F and a high set point of 33F. This temperature cycling is accomplished through a control system that actuates a solenoid valve to start and stop the coolant flow. When the temperature at the deck-pans reaches 33F, the valve opens allowing coolant to flow through the deck-pans. When the temperature reaches a low of 29F, the valve closes stopping the coolant flow.

This manner of operation is called pulse-flow control since the coolant flow is continuously cycling between either fully on or fully off. It is a simple and effective way of controlling the temperature of the deck-pans. But its real benefit comes from the effect it has on tiny amounts of moisture in the air surrounding the deck-pans that freezes and thaws as the deck-pans cycle. This constant freezing and thawing of minute amounts of moisture creates a high humidity area immediately surrounding the deck-pan and any product sitting on it.

The design of the system also includes a heat exchanger at the top of the case to maintain air temperature. The difference between this heat exchanger and a traditional gravity coil is that this one uses pulse-flow controlled coolant, just like the deck-pans. Therefore, the same humidity effect surrounding the deck-pans occurs around the heat exchanger to keep case humidity high.

Traditional convection-type cases have to use of misting systems in order to reduce product moisture loss. Conduction cooling systems, on the other hand, are able to maintain high levels of humidity, and product quality, without having to resort to adding moisture. High moisture levels keep the product fresher longer and reduce shrink. The potential for bacteria growth, that misting systems can promote, is also greatly reduced. This is effect is all the more important with conventional seafood displays that rely on ice to help maintain product freshness. With conduction cooling, ice is not needed. In fact, ice is actually counterproductive in these cases since it interferes with the pulse-flow control strategy.

By going the conduction cooling route and eliminating the use of ice, seafood departments can reduce labor costs and streamline their merchandising procedures. Product doesn’t have to be removed overnight from the case since there is no loss of cooling that goes along with melting ice. So many retailers will keep product up to three days in conduction cases and realize even greater labor savings compared to those using traditional cases from which the product must be removed nightly.

One other advantage, as far as reductions in labor costs goes, is that since the conduction-cooled case has no coil in the bottom of the case, they are easier to clean. This arrangement also reduces maintenance costs. Without a coil at the bottom of the case, deck pans and product don’t have to be removed if there’s ever a problem.

Moist and even cooling are hallmarks of the conduction approach to refrigerated display case design. Conduction cooling is a far more efficient means of cooling than convection. Nearly every BTU of cooling that flows through a conduction-cooling deck-pan goes to cool the product in contact with it. Very little of it is wasted cooling the surrounding surfaces.

Bill Katz is a technical writer at the Hill PHOENIX Learning Center, Conyers, GA. He can be reached at [email protected]