Understanding A2L Refrigerant Fundamentals Within the Regulatory Landscape

The transition from hydrofluorocarbon (HFC) refrigerants to lower-global warming potential (GWP) alternatives is underway in U.S. HVACR sectors. Achieving future GWP reductions will require the use of some existing and new refrigerant options — of which many of the emerging candidates are classified as “lower flammability” A2L refrigerants. Recent updates to refrigerant regulations, safety standards and building codes are enabling the adoption of A2L refrigerants.

Although these refrigerants offer the potential for lower GWP and wide applicability across a spectrum of self-contained and remote commercial refrigeration applications, A2Ls are still a largely unknown commodity. Many stakeholders have a variety of questions and concerns that need to be addressed — mainly regarding their lower flammability classification.

To help answer these questions, Copeland recently produced an A2L Experts video series, in which Joe Summers, senior product manager for Copeland, and I introduce A2L refrigerants, provide an overview of the regulatory landscape, and explain the safety standards.

This article provides additional details to help support a greater understanding of A2L refrigeration. Visit Copeland's A2L webpage to see the videos: bit.ly/CopelandA2Lvideos

What does the A2L refrigerant classification mean?

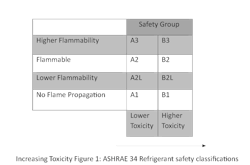

A2L is a class of refrigerants that is defined by ASHRAE 34 as having lower toxicity and lower flammability (often referred to as mildly flammable). The ASHRAE 34 standard denotes refrigerant safety classifications with an alpha-numeric character shorthand. The first letter in a refrigerant classification is its toxicity rating, followed by a number to indicate its flammability rating. An additional subclass delineates flammable refrigerants that burn very slowly, indicated by the third letter in the sequence: L. Thus, A2L is defined as:

- A = lower toxicity

- 2 = lower flammability

- L = low burning velocity.

|

|

Lower-GWP A2Ls refer to a broad group of refrigerant types and blends including, but not limited to, pure hydrofluoroolefins (HFOs), pure HFCs and various combinations of both components. HFOs are a relatively new type of refrigerant alternative that were introduced to provide favorable environmental and performance characteristics. They are composed of at least one double-carbon bond. Not only do HFOs have zero ozone depletion potential (ODP), but they also reside in the atmosphere for a shorter time than legacy HFCs — resulting in GWP levels below global regulatory thresholds of 300 and 150. Many emerging HFOs are used in blends to provide specific GWP and performance characteristics. In the U.S., some HFObased A2Ls are already approved and widely used within AC applications, including 1234yf and 1234ze.

Are A2Ls approved for use in commercial refrigeration?

In 2024, the Environmental Protection Agency (EPA) approved new A2L refrigerant options under its Significant New Alternatives Policy (SNAP) program, SNAP Rule 26, including: HFO-1234yf, R-454A, R-454C, R-455A, R-457A, R-516A and HFO-1234z. The SNAP 26 proposal enables A2Ls to be used in much higher charges than R-290 (i.e., pounds compared to grams), which would make them likely substitutes for legacy HFCs such as R-404A and HFC-134a. Mildly flammable A2L refrigerants are also approved for use in commercial refrigeration in many countries and/or regions around the world.

In 2023, under the authority of the American Innovation and Manufacturing (AIM) Act, the EPA published its Technology Transitions rule, which mandates new GWP limits and higher-GWP HFC restrictions across multiple HVACR sectors. Lower-GWP A2L refrigerants are among the approved alternatives that will help to meet these sector-based limits.

Which states have updated building codes that allow for the safe use of A2L refrigerants?Building codes that regulate refrigerant use are adopted at the state or local levels. In recent years, industry has worked with states to update their building codes to support the safe use of A2Ls. Please refer to the AirConditioning, Heating, and Refrigeration Institute’s (AHRI) A2L refrigerant building code map to check the state and local building codes in your region.

Why Are A2Ls Gaining in Popularity?

Global, federal and state regulations are driving the HVACR industry to transition to refrigerants that have a lower GWP than legacy HFCs. At the same time, many companies are setting aggressive short- and long-term sustainability and decarbonization targets, and the use of lower-GWP, energy-efficient equipment is essential to meeting these goals. Already in use in the global residential AC sector, A2Ls offer the promise of wide applicability across many types of HVACR equipment. Industry experts anticipate A2Ls to become commonplace in future commercial refrigeration and AC applications.

How do recent updates to safety standards set the stage for wider A2L adoption?

The 2021 update to the Underwriters Laboratories (UL) 60335-2-89, 2nd edition product safety standard was the first key step in enabling wider adoption — and supporting the imminent regulatory approval — of mildly flammable A2L refrigerants in commercial refrigeration. ASHRAE standard 15 was updated in 2022 with new guidance for A2L and A3 refrigerants in refrigeration systems, specifying requirements for safe design, installation and operation. The recent SNAP 26 ruling approved the use of A2Ls across a wide range of HVACR end uses.

When will mildly flammable refrigerants be used in commercial refrigeration and air conditioning?

A precedent has already been set for the use of flammable refrigerants in HVACR. For example, propane (R-290) is classified as an A3 (higher flammability) refrigerant, and has been used in low-charge, selfcontained commercial refrigeration units for more than a decade. Select A2Ls have been approved and are currently in use in residential and automotive AC applications. As the industry transitions toward lowerGWP alternatives — and the supporting regulations, codes and standards are in place — mildly flammable A2L refrigerants will become more widely adopted. The EPA’s SNAP 26 ruling approved a variety of A2Ls for commercial refrigeration.

Are there any non-flammable refrigerants?

The natural refrigerant carbon dioxide (CO2; refrigerant name R-744) is a fully non-flammable refrigerant. As such, ASHRAE 34 gives R-744 an A1 classification (lower toxicity and lower flammability). However, although many legacy refrigerants also have an A1 classification, they have the potential for flame propagation — though very low — and will burn under specific circumstances. Thus, those refrigerants are also classified by ASHRAE 34 as A1s with a lower flammability designation.

How safe are the A2L refrigerants used in refrigeration systems?

Industry organizations and regulating bodies have conducted extensive research on the safety of A2L refrigerants in commercial refrigeration systems. To cause a flammable event, three conditions must be present:

1. Equipment must develop a leak.

2. The concentration of leaked refrigerant must exceed the lower flammability limit (LFL) threshold.

3. A flammable source of ignition must be present (e.g., a flame or high-ignition energy source).

LFL is the lower bounds of the concentration level at which a flammable refrigerant could ignite; conversely, the upper flammability limit (UFL) is the higher bounds of this concentration level. For a flammable event to occur, the concentration of flammable refrigerant must fall between these two boundaries.

Product safety standards have taken this research into consideration and developed risk mitigations that are designed to stay below the LFL threshold in the event of a refrigerant leak. Thus, the probability of a flammable event is significantly reduced.

How do product safety standards define charge limits and safe use guidelines of A2L Refrigerants?

Product safety standards, such as UL 60335-2-89, 2nd edition, provide guidance for the safe use of A2L refrigerants in various types of refrigeration equipment. UL 60335-2-89, 2nd edition defines charge limits for self-contained and remote refrigeration systems — and notably supports higher A2L charge limits in remote systems.

One of the benefits of using A2L refrigerants is the potential for increasing equipment capacities via the use of higher charge limits in self-contained equipment. Per the UL 60335-2-89, 2nd edition product safety standard, A2L charge limits for self-contained equipment are determined by multiple factors, which include refrigerated unit design and the LFL rating of the selected A2L refrigerant.

To learn more, visit Copeland.com

R-6072 ©2024 Copeland LP. All rights reserved.

Annex CC testing protocols require original equipment manufacturers (OEMs) to design equipment to prevent flammable refrigerant concentrations in the event of a leak and verify that their equipment with more than 150 grams of refrigerant does not exceed 50 percent of the refrigerant’s LFL for an extended period.

For more information about the safe application of A2L refrigerants, please visit the E360 content hub. To learn more about the regulations driving A2L adoption, please visit the regulations page on our website.

About the Author

Jennifer Butsch

Director, Regulatory Affairs for Copeland

Jennifer Butsch is director, regulatory affairs, for Copeland. Jennifer is responsible for managing activities related to Copeland’s policies, regulations, codes and standards as they apply to the HVACR market.

Jennifer earned a Bachelor’s Degree in Biomedical Engineering from Wright State University and a Master’s Degree in Business Administration from the University of Phoenix. She is actively involved in several industry organizations, including AHRI, ASHRAE and Women in HVACR.