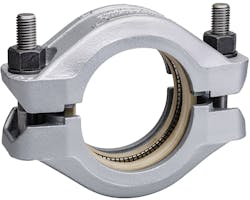

Victaulic Style 870 Coupling

Victaulic has developed the world’s first grooved piping system for saturated steam and condensate piping, sources say. Designed for use on commercial and industrial steam applications, the system features the Style 870 rigid coupling, a full line of fittings, and pipe preparation tool roll sets to process the new OGS-200 groove profile. The Victaulic grooved steam system eliminates the need to weld steam piping with pressures up to 150 psi (1,034 kPa) and temperatures up to 366 degrees Fahrenheit (186 degrees Celsius). Victaulic steam couplings and fittings ease installation and maintenance, compress the construction schedule, reduce downtime, and maintain a safer, more productive worksite.

“Engineers have long relied on the superior performance and design flexibility of Victaulic systems, while contractors depend on the total installed cost and time savings. We’re pleased to bring these benefits to steam systems for the first time,” said Kurt Gobreski, director of valves & large diameter systems with Victaulic. “This tremendous technological advance allows those who design, install and maintain steam systems to experience the absolute confidence that comes with specifying Victaulic.”

Joining steam piping with grooved couplings enables faster, easier installation than welding, threading and flanging. Pipe is joined by positioning the coupling seal and housing segments on the pipe ends and tightening the bolts and nuts to the specified torque requirement. Installation is completed up to five times faster than other joining methods.

With a union at every joint, the Victaulic steam system enables quick, simple maintenance, reducing downtime. The couplings simplify access to system components and ease pipe replacement and system expansion. Unlike flanged joints, Victaulic Style 870 couplings last the life of the system without regular maintenance. The couplings can also be used as a maintenance solution for existing steam piping, enabling leaks to be fixed quickly and inexpensively.

Victaulic Style 905 Refuse-to-Fuse™ HDPE Coupling

Up to 10 times faster than traditional fusing, the Victaulic Style 905 Refuse-to-Fuse™ HDPE coupling installs without the need to disassemble the coupling. The product can be properly installed using an impact gun or standard socket wrench with no special training or regular certification needed.

Weather is not a factor and no tents are required. No heating or cooling time is required and the product can be installed on new, used or dirty pipe. The Style 905 coupling, available in 2-6-inch sizes, meets or exceeds the rating of the pipe.