By Donald C. Gillis, Senior Training Consultant, Chemours

HVACR service technicians find themselves at the forefront of the refrigerant transition in AC and commercial refrigeration. As hydrofluorocarbon (HFC) refrigerants with high-global warming potential (GWP) are being phased down, mildly flammable A2L refrigerants have been identified as potential lower-GWP alternatives.

A2Ls have been approved by the Environmental Protection Agency’s (EPA) Significant New Alternatives Policy (SNAP) Rule 23 for use in residential AC applications as of June 2021. Approved refrigerants include the commonly known R-454B and R-32, which are deemed acceptable subject to use conditions.

If you’re an HVACR technician, it’s likely that you will soon encounter A2L refrigerants in the field. So, it’s important to gain a better understanding of A2Ls to maximize safety and assist your customers with installation and service calls.

Thankfully, from a service perspective, the transition from existing refrigerants to A2Ls will not require a fundamental shift in the way you conduct business. However, it will require more rigorous attention to basic servicing fundamentals. Existing recommended best practices for A1 refrigerants will continue to apply—with the addition of a few special considerations, new equipment, and A2L-rated tools.

What Are A2Ls?

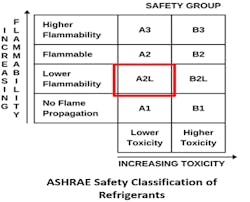

A2Ls are considered “mildly flammable” and consist of HFCs, hydrofluoroolefins (HFOs), and various blends of the two synthetic refrigerants. Many of the emerging lower-GWP refrigerants fall into the A2L category and will be used to comply with emerging environmental regulations.

The A3 refrigerants like propane or (R-290) have been used in self-contained refrigeration since the EPA approved it in its SNAP 20 ruling. Many of us understand A3s like R-290 to be highly flammable, and it’s natural to have similar concerns about flammability when working with A2Ls. However, when it comes to flammability, A2Ls are quite different from A3s.

Comparing the flammability differences between A2Ls and R-290 is crucial to understanding service considerations and relative safety risks.

Consider the following key flammability criteria:

1. Lower flammability limit (LFL)

A2Ls’ LFL are ~8X higher than that of R-290. As such, these refrigerants are less likely to form flammable concentrations if leaks occur. That allows for potentially larger charge sizes and applications.

2. Minimum ignition energy (MIE)

R-290 has a very low MIE and can be more easily ignited by lower energy sources such as static electrical discharge. The MIE for A2Ls is significantly higher; these refrigerants require an open flame or strong electrical energy source to sustain an ignition, making A2Ls safer to use with electrical components.

3. Heat of combustion (HOC)

HOC values are much lower in A2Ls than R-290, resulting in a lower severity of ignition events.

The potential for flammability makes the use of leak sensors and detection equipment a more important system consideration with A2Ls. Otherwise, A2Ls have very similar characteristics and pressures as common A1 HFC refrigerants, such as R-410A.

Compared to installing or repairing A1 refrigerant-based systems, A2Ls introduce several new required steps. However, these are all considered industry-accepted best practices for A1s. So, those of you already performing these steps will notice little change to your standard procedures.

Moving from A1 to A2L

It’s very important to remember that A2Ls are not drop-in replacements for A1s in existing HFC systems; all HVACR equipment must be designed and rated to use A2Ls. While the process of charging an A2L system is like that of charging an A1 system, technicians must ensure that they do not exceed the maximum allowable charge limits.

Note: new safety labels will soon appear on A2L-based HVACR equipment to alert contractors of additional precautions. Some may also include a panel designed to cover service ports. For more information, please visit the Air-Conditioning, Heating, & Refrigeration Institute’s (AHRI) Safe Refrigerant Transition Task Force website.

A2L reclaim and recovery cylinder differences

Although A2L cylinders have the same rated pressure as current R-410A cylinders, tanks are designed with several distinguishing characteristics:

Pressure relief valve — In the event of excessively high cylinder pressure, A2L cylinders include a pressure relief valve that’s designed to release only enough refrigerant to reduce the pressure in that cylinder. Upon release, the valve will reset.

Red band/stripe — A2L cylinders will have a red band (stripe) or the entire top painted red to indicate the presence of the mildly flammable refrigerant.

Left-handed (LH) thread — To further distinguish from other types of refrigerants, A2L cylinders will most likely have an LH thread.

That’s a brief overview of the changes you can expect to see in the field as the industry moves forward with A2L refrigerants. Some things may look different, and your practices may require a bit of extra care. But again, if you understand the safety and service considerations of A2L refrigerants and have been using A1 best practices all along, these changes will probably come to you easily.

NOTE: Chemours and other industry-recognized stakeholders offer A2L training. It’s advisable to investigate this type of A2L training to familiarize yourself with the new A2L safety and handling practices moving forward.

Sponsored By: