A contractor called our office with a question about oval duct airflow performance. It’s a typical concern that we hear from time to time, usually because when oval duct is installed in homes, it moves less air than what the designer expects.

In many areas of the U.S., oval duct usage in homes is declining because of cost and the increasing popularity of flex duct. But in some areas in the North and East regions, oval duct is increasing in popularity. Its rise, unfortunately, is due to architects failing to provide adequate space to install ducting, which leaves the installers little room to fish ducting through the walls. Whatever the reason, unless reasonable expectations of airflow delivery are met, the end result may be an extremely poor performing HVAC system.

As we looked at the airflow test data that we collect at NCI headquarters, we found some disturbingly low airflow delivery numbers for oval duct. Not surprisingly, we found these airflow numbers differ significantly from generally accepted industry engineering numbers. Or in other words, the CFM on the oval duct design charts that our Dad’s gave us doesn’t show up once the ducts are buried in the walls.

ACCA Manual D, the foundational standard for designing duct systems in our industry, provides ample engineering data to calculate oval duct airflow. However, many contractors fail to apply all the steps required to accurately estimate the final results. We’ve found that the idealistic laboratory tests performed by SMACNA in the 1950’s and 60’s are so far off from the installation conditions we are stuck with in today’s homes, that the chance for error is tremendous.

Design Recommendations

To make this simple, the only way to know for sure what airflow a duct will deliver is to measure its performance once it’s installed and has been attached to working equipment on a balanced system. That’s quite a way down the road, considering we’re discussing the design process at this moment.

Installation conditions can greatly affect airflow. The static pressure capacity of the fan can make a big difference. The duct configurations installed before and/or after the oval duct can have a huge impact on airflow. Also, the elbows tucked into a building before or after the oval duct appear to be another reason for low airflow. Squishing ducts up through a limited space between walls is a less than ideal condition.

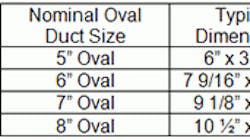

If oval duct must be used, we’ve to start with reasonable expectations of the airflow that the duct can deliver. We have prepared the following table based on live data that we have collected from hundreds of tests taken in the field. We receive this live data almost daily from across the country and believe that contractors are the best source of airflow data in the world. Check out these numbers:

We’ve found that the average airflow delivered by oval ducts, under normal installation conditions, may be estimated by setting a metal duct calculator to .04" friction loss per 100 ft. on a metal duct calculator. This is derived from what we have measured in the field and what and will work properly if the duct is installed correctly and the fan has been sized to move the required airflow.

One interesting observation that can help you in the field is to know that an oval duct will normally move a little more than half the airflow of a round duct with the same area when it’s installed in the field. Scary, isn’t it?

If you question this idea, the remedy is to duct off of your balancing hood and measure your system performance in the field. When you execute this test, the fat lady sings and the play is over.

Temperature Loss

While we’re discussing oval ducts, there’s one other problem that should be mentioned. When oval ducts are installed in outside walls, it often leaves little room for duct insulation. This is especially true in older homes that have thinner wall structures.

So in addition to producing lower than expected airflows, the temperature loss or gain in theses ducts is often many times more than ducts located in inside walls or between floors, due to little or no insulation between the duct and the exterior skin of the building.

On a day when there are extreme weather conditions, measure the air temperature entering the duct, and then the temperature exiting the uninsulated oval duct in the wall. Subtract the two temperatures to find the temperature loss or gain through the ducting. If it’s more than a degree or two, you should add insulation, but that’s another problem all together.

Good stuff

The purpose of this article isn’t to bad mouth oval duct, but simply to identify reasonable expectations and to provide a perspective when designing and installing oval ducts. Also remember, engineering is only a designer’s idea of what should happen in the field. The only proof of what did happen is to measure and verify final system performance after installation.

Rob “Doc” Falke serves the industry as president of National Comfort Institute, a training company specializing in measuring, rating, improving and verifying HVAC system performance. If you're an HVAC contractor or technician interested in a free NCI Duct Sizing Table, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, technical articles and downloads.

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.