Editor's note: The following article is based on "Constant Commissioning for Continual Energy Efficiency," presented by Optimum Energy LLC during the Contracting Business.com Commercial HVACR Symposium and HPAC Engineering magazine's seventh annual Optimum Buildings Conference, held Sept. 23-24 as part of HVACR Week 2010.

The 2011 HVACR Week — which includes HVAC Comfortech, the HVACR Commercial Symposium, and the Optimum Buildings Conference — will be held Sept. 21-23, Indianapolis, IN. visit HVACRWeek.com for information.

Although HVAC typically represents 40% of a commercial building's total energy use, energy efficiency historically has taken a back seat to occupant comfort in commercial-building HVAC design. With energy prices on the rise and commercial-building owners searching for ways to be more competitive, satisfy corporate social- responsibility objectives, and meet new government mandates, however, energy efficiency is becoming a greater and greater priority.

Today, HVAC systems must do more than provide a comfortable environment. They also must:

- Achieve the highest levels of energy efficiency to minimize operating expenses.

- Sustain reduced energy levels to ensure savings over time.

As difficult as energy-efficient HVAC can be to achieve, it can be even harder to sustain. Even the newest state-of-the-art HVAC systems can experience “drift,” or degradation in performance resulting from malfunctioning mechanical and control equipment.

Conventional Solutions

The HVAC industry has developed a variety of approaches to optimizing HVAC-system performance. The most widely recognized is recommissioning, a process that includes an assessment of a system, identification and correction of mechanical and control issues, development of new operating procedures, and, often, implementation of new energy-efficiency strategies.

One such energy-efficiency strategy is the use of variable-speed equipment and custom-developed control methodologies. While some level of savings usually is achieved with this approach, it is not without risk. Custom solutions are unproven, can take weeks or months to program, and require hands-on functional testing to verify a system is working as designed. Additionally, without real-time measurement and verification, determining whether predicted energy savings have been realized and/or are being sustained is difficult.

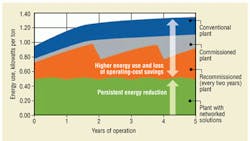

With recommissioning, building operating-efficiency improvements typically range from 5 to 20%. Because recommissioning is focused on improving efficiency at a single point in time, however, recommissioned plants—even ones maintained to the highest standards—are subject to drift until they are recommissioned again.

Savings Opportunity

Building operators able to maintain HVAC systems consistently and mitigate performance drift have the opportunity to reduce operating costs reliably over the long term. This is vitally important to ensuring investments in energy reduction achieve expected returns.

A new means of ensuring optimized plant operation is the use of enterprise applications with integrated software solutions. Today, integrated software solutions capable of networking all of the equipment in an HVAC system and optimizing energy-system operation for maximum energy efficiency are available (Figure 1).

HVAC systems capable of providing occupant comfort, as well as annual wire-to-water energy efficiency of 0.4 to 0.6 kw per ton, achieve a new standard of HVAC-system performance: ultrahigh.

Integrated Software Solutions

Today, commercial-building owners and operators are reducing HVAC energy consumption by 30 to 60 percent with networked applications combining advanced relational-control methodologies and Web-based measurement, verification, and management services. Mineta San Jose International Airport in San Jose, Calif., for example, reduced HVAC energy use by more than 1.25 million kwh, or 50%, in 12 months by implementing an integrated software solution that includes control-software components that automatically and continuously optimize the operating efficiency of the entire HVAC system based on real-time building loads.

Since implementing the integrated software solution, Mineta San Jose International Airport has maintained a monthly wire-to-water energy efficiency of 0.61 to 0.65 kw per ton.

Measurement, Verification, Management

Web-based measurement, verification, and management services can provide continuous feedback, including detailed real-time and historical performance data that enable operators to detect, diagnose, and resolve HVAC-system faults quickly. An on-site controller captures and transmits equipment operating information (typically, hundreds of points per system), which is stored in a secure database. This data can be used for at-a-glance dashboards or to provide historical measurement and verification reporting and analysis (Figure 2).

Measurement, verification, and management data can be used in a variety of ways to streamline plant operation and maintenance and ensure energy reduction is persistent. For instance, they can be used to automatically generate supervisory-level alarms that inform building operators and technicians when an exception condition is compromising the energy-efficient operation of an HVAC system. Detailed equipment trend data are accessible in easy-to-read charts and graphs, enabling fast diagnosis of system faults—even though hardware alarms may not have been triggered, and overall performance of the plant may not be noticeably impaired.

In conventionally operated plants, performance to specification often is assumed. Unless the building undergoes recommissioning, however, this assumption never is verified. System faults may go undetected for long periods of time, until scheduled maintenance or occupant complaints uncover hidden problems.

Integrated software solutions take the guesswork out of HVAC operations, allowing building operators to continuously commission a building for optimal energy performance. With on-demand reporting and analysis capabilities, building owners and operators no longer have to rely on physical-plant inspections or labor-intensive functional testing to detect and diagnose faults.

Summary

With rising energy costs and increased pressure to be "green," focusing solely on occupant comfort no longer is enough. Building owners looking to maximize their investments must consider energy efficiency and persistent HVAC performance. While custom solutions and recommissioning can result in energy savings, they are expensive and carry some inherent risk. Just as important, they do not leverage the data available via a building-automation system to sustain high-level energy reductions over the long term.

Sustaining high efficiency requires a new approach to HVAC-system design, control, and operation. Integrated software solutions combining demand-based energy-reduction software and an ongoing online energy-management tool are the key to achieving ultrahigh-performance HVAC and guaranteeing intended payback and long-term value. Today, by applying integrated software solutions, it is possible to more optimally control commercial HVAC systems and fundamentally change the way buildings are managed and maintained.

Jim Hanna is co-founder and chief technology officer of Optimum Energy, LLC. a provider of HVAC software solutions. He has more than 25 years of experience developing information-technology products and systems. Previously, he founded and served as vice president of product development for Applied Voice Technology, developer of open-messaging platforms.