Fast Installation and Zero Plumbing Leaks for Six-Story Facility

The high cost of installing a plumbing system in any facility breaks down to materials and labor costs. Materials includes all the piping and fittings costs, which can be priced out fairly well early on in the project. Labor costs, on the other hand, are variable and split between installation time and the time it takes to repair any leaks before finalizing the installation.

When Aaron Trask, VP of family-owned Parkway Construction Services (Nashville, TN and St. Louis, MO), won the bid to plumb the new multi-purpose living-learning center facility on the Meharry Medical College campus (see Figure 1), he contacted Chris Richey, Outside Sales Rep at Kenny Pipe & Supply (Nashville, TN), for his piping and fitting needs. The project was for a six-story facility that would feature 126 apartment-style units, flexible teaching spaces, a parking garage, retail spaces, office, and much more.

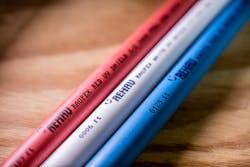

Trask understood that replacing the original specification for copper piping with PEXa piping would provide the high-quality performance he wanted while saving money in material costs. Prior to making a final decision, he consulted with Richey about which system to purchase. According to Richey, “There are different PEXa piping systems available, but I recommended the REHAU RAUPEX UV shield crosslinked polyethylene pipe combined with the EVERLOC+ compression-sleeve fitting system, which I thought would be the fastest to install and offer the best performance for a PEXa system available. Plus, the system is very competitively priced.”

Trask was familiar with PEXa products but had not used RAUPEX pipe or EVERLOC+ fittings before. Nonetheless, he was confident in Richey’s recommendation. Once he and his team started installing the system, they immediately noticed differences compared to their prior PEXa installs and found that they could confidently plumb four rooms per day. Once the pipe is installed, the EVERLOC+ fittings are installed with a fast, consistent process requiring only two expansions and one compression using an easy-to-use proprietary tool. The installer simply expands the pipe, inserts the fitting, and the sleeve compresses the pipe over the fitting to create the seal. The fittings feature a textured PEXa compression sleeve with four sealing edges that protect against leaks. The company offers battery-powered tools such as the heavy-duty EVERLOC+ compression-sleeve tools with quick-change expander heads and color-coded compression jaws sized for up to 2-inch pipe (see Figure 2a and 2b).

According to Trask, “With other PEXa brands, you can’t tell if the crimp is made properly and have to wait for the pressure test to know if it worked. With the EVERLOC+ fitting, it just takes a few steps to create a true mechanical joint that doesn’t solely rely on the memory of the pipe, so you can immediately see that the connection is made successfully and is leak-tight.”

According to Richey, another unique and valuable feature of RAUPEX pipe is the REHAU UV shield coating, and related UV-conscious handling. While RAUPEX UV shield pipe is not intended for permanent exposure to sunlight, it is the only PEX pipe with a 1-year UV warranty to protect from exposure during installation (see Figure 3). “UV ray exposure are one of the most damaging things that can happen to PEXa pipe. For example, if it’s sitting in the bed of a truck or outside at a job site for months before being installed, UV rays can cause hidden degradation and pin hole leaks down the road,” Richey explained. Not only does REHAU incorporate a UV shield coating on their pipe, the company also provides additional protection by packaging the pipe sticks and rolls in cardboard to keep UV rays out. Other companies use plastic wrap.

Leak Testing

The Meharry Medical College Living-Learning Center project incorporated more than 4,000 connections using the REHAU RAUPEX pipe/EVERLOC+ fitting PEXa system. Trask explained, “I would say with this number of fittings — 126 units with bathroom, kitchen, and water heaters, and all the other spaces — represents a big job with a lot of plumbing. Typically, in this type of situation, our team would see 50 or so initial leaks, and that would be pretty normal. No problem, we’d go back and fix them.” Although the failure points in plumbing are almost always at the fittings, and not at the pipe, it was impressive to Trask and his team how robust the RAUPEX pipe turned out to be, as well.

Trask mentioned that on most jobs other tradespeople on-site, such as drywallers and the general contractor, would often watch the pressure test and prepare to help mitigate any ancillary damage that might occur from initial system leaks. But on the Meharry College building there were zero leaks.

“That’s right,” Trask said, “the REHAU system was 100 percent leak free. Any contractor would tell you that that’s extremely unusual.” The other contractors on the job seemed to be aware that there were no leaks as well. “People were surprised and talking about it. And that reflects well on me and my company,” Trask said. More importantly, zero leaks meant that there was no rework to be completed, which translates into much lower labor costs for that portion of the project.

It Takes a Team

With great supplier recommendations, an open attitude to working with a new company’s products, and a qualified workforce, Parkway Construction Services was able to install a quality product into a six-story educational facility with no leaks during pressure testing. By incorporating the REHAU RAUPEX pipe/EVERLOC+ fitting PEXa system, Parkway was able to increase installation time and reduce labor overall costs, making the project a widely accepted success.

Project: Meharry Medical College Living-Learning Center, Nashville, TN

Type of construction: Educational facility, opened 2022

Scope of project: 25,000 ft (7,620 m) of RAUPEX pipe, 4,000 EVERLOC+ fittings

General contractor: Whiting-Turner

Plumbing contractor: Parkway Construction Services

Manufacturers’ rep: Hydro Spec Inc.

Distributor: Kenny Pipe & Supply