The next 12 to 18 months should prove even more interesting than the last in the residential HVACR market, with a variety of factors at play. This includes stable retail end-market demand at the consumer level that remains weak, but pretty close to the trough; the expiration of the 25C tax credit; the potential for a significant exploitation of a loophole in the new refrigerant law, which was supposed to be environmentally friendly; and lastly, raw materials-driven price increases, all of which will continue to drive volatility in monthly shipment data (from AHRI). Our starting point for next year is underpinned by the premise that there is some pent-up demand for an industry that remains stubbornly close to trough levels (2009) and that the economy is getting gradually better — meaning we should see some growth off of the bottom, which we peg at around 5 percent. How we get there, however, has many moving parts and, as always, depends somewhat on the weather, which, with all humility, is tough to call.

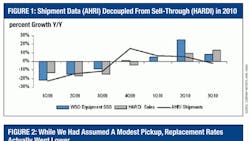

To understand where we are going in 2011, it's important to take a look back at 2010, which was influenced by several economic (unemployment, consumer spending and confidence trends) and nonfundamental (tax credit and R-22 changeover) factors, as well as hot weather. Relative to high expectations, 2010 was disappointing, as condensing unit shipments, which we estimate represent 70 percent of industry value, are probably going to end up only about 1-2 percent. With the installed base growing as it has for decades, this meant the condensing unit replacement rate actually went down from a record low level. However, sell through/retail sales, as measured by HARDI and corroborated by independent distributor Watsco, which includes parts and equipment sales, appear to have been up steadily throughout the summer, an important dynamic, which suggests there were machines breaking down and consumers were spending more money, albeit cautiously. In the end, we believe consumers continued to fix equipment (compressor/motor replacement) instead of replace their machines, a dynamic evidenced by the 10 percent increase in Emerson compressor sales. We believe that this was driven by sticker shock from the high cost of replacement, mostly due to the changeover to R-410A that dramatically raised the price of system replacement, an unwelcome development in a challenging consumer economy. (See Figures 1 and 2.)

To expand on this a bit, R-410A further changed the historical dynamic of fix-versus-replace that used to be a nondecision. This is an important dynamic to understand. Previously, in an all-R-22 world, a fix would cost around $1,800-2,000, lasting three years, while a replacement cost $1,800 to 2,500, lasting around 12 years, coming with an extended warranty. This made the decision to replace easy. The R-410A replacement, however, is $4,000 to 6,000 ~2.5x the old R-22 replacement, not necessarily all because of system cost, but because the entire system, including coil and air handler (AHU), has to be changed out, adding mostly labor cost. In the end, we think this drove some demand destruction for the equipment manufacturers, which we incorporate into our longer term market model. This could be a lingering issue in the years ahead, but certainly makes more of a difference as tough economic times linger.

Page 2 of 2

On the flip side, a positive event this year was the 25C tax credit, which provided a $1,500 tax credit to install a 15 SEER and above system, an initiative that is expected to expire at year-end. Indeed, looking at the early read on mix shows 14+ SEER units were up big, with the biggest move in 15+ units, or those that qualify for the tax credit. We do not think this added significantly to volumes. It was more of a driver of industry revenue/value, adding 1.5 percent. (See Figure 3, below.)

Moving to 2011, given 2010 showed no progress on shipments, we can use 2009 — a year in which the weather was not so good nationally, and the economy was equally as bad — as a good starting point. If R-22 returns as an option for consumer replacement, the price of the systems will be about the same as it was in 2009, driving similar dynamics around fix-versus-replace. What is notable and different, is that we have one more year of aged systems/deferred activity, and the economy is incrementally better (housing and consumer confidence). Several dynamics are at play with tax credit and weather headwinds, while raw materials-related price increases are positives; however, these are minor compared to the economy and the potential return of R-22. Bottom line: we think this year should be better than 2009 in the end, and given 2010 was basically flat, we see growth.

First, on the headwinds, the tax credit is the main issue. We think this added a mixed benefit this year, although only about 1.5 percent in revenues, not units. Assuming the march to more efficient systems continues, we see this subtracting only a similar amount next year. Second, weather was obviously good in 2010, and that is tough to call. If we assume weather is normal, it would still be better than 2009, but not as good as 2010.

A significant swing factor, which we think will be positive and deal with some of the 2010 demand destruction headwind, is the emergence of “dry-ship,” or the return of R-22. Nitrogen-charged R-22 unit replacement is much less expensive for the consumer to install. We think more would choose to replace than repair if OEMs, contractors and distributors choose this route. We see two impacts here. First, we think this is a positive for unit volumes, and second, the replace-fix decision is more favorable at the lower price point. Keep in mind that this should hurt volume in other ways, given the lower degree of components that go along with an R-22 sale, as the attachment rate for coils and AHUs is higher with R-410A, though, from a value perspective, the condensing unit is worth almost 3 times more than components. There will be some shift in share toward the more aggressive lower end players, but we expect all to participate and benefit about equally in the end. To be sure, there is some uncertainty here as to whether this actually comes into play or not. The EPA is having internal deliberations, and DOE just released for public comment a proposed method for dealing with these products. However, most OEMs believe the loophole will remain in place. If it does, history in this industry has shown a strong preference for the best value. The pre-buy for 10 SEER product during the 13 SEER transition, along with the more muted pre-buy of R-22 this past December, shows that contractors and distributors continue to believe there is a price-sensitive market here.

In the end, much more than these industry specific dynamics, it's all about the economy and consumer sentiment/employment. This is the No. 1 driver of the replacement rate over time. Importantly, from the base of 2009, we see housing up and consumer sentiment up, which means there should be some lift in the replacement rate from 2009, but on a higher volume of aging equipment as the installed base will have aged another year or two. (See Figure 4.)

Add to these factors broken equipment that has been fixed or deferred, or “pent-up” demand, which we estimate could be more than 5 million units, and there is upside potential to the 5 percent. In the end, we had expected 10 percent+ growth in 2010 and only got 2 percent. Our refreshed industry model pushes the recovery out a year, as we continue to see gradual improvement in retail (HARDI shipments) with the economy, and pent-up demand, with the same potential for 10 percent+ growth, with 5 percent as a starting point while the “dry-ship” factor looms large as a potential, albeit uncertain, positive.

Steve Tusa is an analyst with JP Morgan Electrical Equipment & Multi-Industry Equity Research. Contact him at 212/622-6623 or [email protected].