If you want to reverse engineer a bad residential duct system, start with supply register sizes. Count the number and size of the registers per system. If they all measure 4x10 inches and work out to four 4x10-in. supply registers per ton, expect problems. Rule of thumb designers and installers often assume each supply register will deliver 100 cfm (4 x 100 = 400 cfm per ton).

Last month, I walked through a recently renovated house with a friend. Curiosity got the best of me, and I looked at the ceiling registers. Sure enough, they were all 4x10s. I counted 16 supply registers. The next stop was the outdoor unit, where I noticed the model number had a “48” in it. You guessed right – it was a four-ton unit. The installing contractor used the old four 4x10-in. registers per ton rule of thumb.

Rule of thumb designers and installers often assume each supply register will deliver 100 cfm (4 x 100 = 400 cfm per ton).

It's unfortunate, but many in our industry overlook the importance of supply registers. I was in this group for longer than I care to admit. I thought the only reason for a supply register was to cover the rough supply openings of the duct system. We used the cheapest options but didn't know those were rarely the best choice.

The day I learned about how throw and spread affect air movement, I never looked at supply registers the same way again. Let's look at these two traits to see how they influence air movement and help you solve comfort problems.

Throw and Spread

Throw is the distance from the register air will travel. It has a corresponding velocity, usually 50 fpm (feet per minute), to determine throw distance. The term for this trait is terminal velocity. A good register should throw air at least 75% of the room distance you're conditioning. Let's say you're using a ceiling supply register, and the room is 10-ft. tall. You would need a register with a minimum throw of 7.5 feet (10 ft. x 75% = 7.5) to mix the room air.

Spread is the largest width the airstream will travel at terminal velocity. One factor determining the amount of spread from a register is the angle of the register vanes. Typical vane angles are 0˚, 22˚ , and 45˚. The smaller the supply register vane angle, the farther air will throw. As the airstream spread from the registers increases, the throw will decrease.

Manufacturers test and rate supply registers using air temperature from the register that's identical to the test room air temperature. Most manufacturers use 70° F ambient air in their tests and refer to them as isothermal conditions.

In the field, throw and spread change as supply air temperature changes. Expect a 30% reduction in throw and spread in cooling mode because cooler air is heavier. Heating airflow typically gets a 30% increase because heated air is lighter.

Stay in the Zone

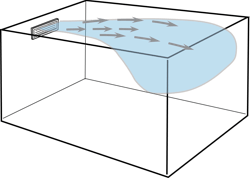

As air leaves a supply register, the vanes or louvers compress and force the air through. This action is like placing your thumb over the end of a water hose to make the water stream travel farther. As air follows this same principle, it causes conditioned supply air to mix with room air in an interaction known as air entrainment.

Because of this interaction, a well-placed supply register delivering 100 cfm (cubic feet per minute) of airflow can set 10 to 20 times the amount of room air into motion. Your job is to make sure the air motion takes place in the proper zones.

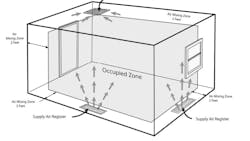

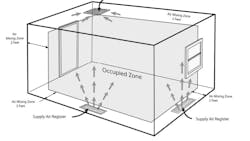

There are two zones in any conditioned room necessary for proper air mixing. First is the Air Mixing Zone. It’s an area located near the walls and ceiling of a room, typically within two feet. Second is the Occupied Zone. This is an area surrounded by the Air Mixing Zone. It’s the area where your customers live (See Figure 1).

The existence of these two different zones is vital to understanding effective air mixing and room ventilation. The general idea is to deliver supply air into the Air Mixing Zone and select supply registers that keep air velocity to a minimum in the Occupied Zone.

When air mixing doesn't occur properly in these two zones, comfort problems prevail. To quote my friend Ed Janowiak, "Don't blow air on people." If you understand the two zones and consider throw and spread, you'll solve and reduce customer complaints.

Supply the Right Registers

It's a safe bet your installations don't perform as intended if you use the four, 4x10 supply register per ton rule of thumb. Just because a supply register fits in a boot opening doesn't mean it will work. There are some 4x10 models that only deliver 24 cfm!

Register manufacturers all have throw and spread specifications listed in their supply register options. Most make it easy to find those specs. You need to know who made a particular register so you can check its specifications. When these two traits work together, they make a big difference in room comfort.

If you run into issues with large room temperature variations, air that seems stagnant, or drafts, consider the supply register characteristics above. You may surprise your customers with how a simple register upgrade corrects an uncomfortable room.

David Richardson serves the HVAC industry as vice president of training for National Comfort Institute, Inc. (NCI). NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.

If you're an HVAC contractor or technician interested in learning more about measuring duct system performance, contact David at ncilink.com/ContactMe. NCI's website www.nationalcomfortinstitute.com is full of free information to help you improve your professionalism and strengthen your company.

David Richardson serves the HVAC industry as vice president of training for National Comfort Institute, Inc. (NCI). NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.

If you're an HVAC contractor or technician interested in learning more about measuring duct system performance, contact David at ncilink.com/ContactMe. NCI's website -- www.nationalcomfortinstitute.com -- is full of free information to help you improve your professionalism and strengthen your company.

About the Author

David Richardson

Director, technical curriculum

David Richardson serves the HVAC industry as director of technical curriculum at National Comfort Institute, Inc. (NCI), Avon, Ohio. NCI specializes in training that focuses on improving, measuring, and verifying HVAC and Building Performance.