Trane Provides Dealer Support in Time of Change

We continue our 2024 series of interviews with representatives from some of the leading HVACR brands, as heating, air conditioning and refrigeration contractors and their technician teams prepare to operate by some new ground rules related to high GWP refrigerant phasedowns and adoption of alternative A2L refrigerants. This month, we feature Trane. Trane Residential and Trane Technologies are committed to transitioning to low global warming potential (GWP) refrigerants in compliance with global environmental goals and new federal regulations.

This month, we feature Trane. Trane Residential and Trane Technologies are committed to transitioning to low global warming potential (GWP) refrigerants in compliance with global environmental goals and new federal regulations.

Leadership for these brands know they have a responsibility to inform and educate their dealers to install their products properly and provide the most informed expertise for a homeowner. In doing this, dealers and technicians can benefit from client referrals, customer satisfaction, and remain competitive in their local markets.

We spoke with Eric Weiss, Technical Trainer for Trane Technologies Residential Solutions. Weiss's background includes work as an HVAC technician and as the owner of an HVAC business during the late 1990s to early 2000s. Our discussion focused on four topics:

- the role of Trane Comfort Specialists and representatives during the transition to A2L refrigerants and wider adoption to inverter technology.

- the "Plug-and-Play" design of Trane’s new low GWP products that now allow technicians to replace a homeowner’s current system and furnace easily without the time-consuming element of retrofitting or rewiring the system, saving dealers time and costs.

- Trane Residential's plan to phase in low-GWP refrigerants into its products, beginning with the 15 SEER2 heat pump in 2024.

- Trane's recently-announced new naming and tiering system, to help consumers better understand which product is best for their homes.

Contracting Business: Eric, how is Trane assisting their dealers during the refrigerant transition and adoption of new technologies?

EW: As a technical trainer, I spend most of my time working with contractors, technicians and dealers in a training capacity, to make sure they're up-to-speed on the latest Trane products, and that they understand the challenges they will encounter in the field.

Today, our dealers are trying to keep up with the changes, not just with A2L refrigerants, but in increased efficiency products. PSC (Permanent Split Capacity) motors are now giving way to inverter technology. This trend started with gas furnaces about seven years ago due to a Department of Energy requirement to attain better blower efficiency. Then it transitioned to air handler and package unit platforms, and is becoming more popular with compressor drives.

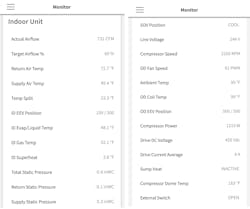

PSC motors are fairly consistent from one manufacturer to another. However, in the inverter world, that game changes. Every concept will be similar related to filtering processes to clean up the power, and there will be capacitors to store the power, and some kind of control logic to drive that three-phase motor. But the layout and discharge time will be different. You look at a variable speed motor and it may say to wait two minutes or five minutes. Some compressor drives may take up to 20 minutes to discharge and provide safe working conditions. With Trane’s inverter systems, we discharge within two minutes and we’ll either incorporate resistors to discharge as heat within the drive, or use the compressor windings. Inverter technology adds complexity to the system. Different manufacturers may incorporate their inverter controls into a single “drive” board, or they may separate the inverter or controls into two or three individual control boards within the unit. Manufacturers will use different sensors and control logic for compressor operation and reliability. Inverter systems can provide improved system efficiency as well as improved comfort for the homeowner. Unfortunately, this can make life more challenging for the contractors and technicians who must stay on top of advancing technology. Continued training and education are key.

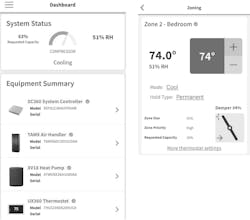

CB: Trane's ComfortLink II "Plug-and-Play" control was introduced in 2011 as an in-home monitor and aid to greater HVAC system efficiency by providing a better communication path between the thermostat and the indoor and outdoor HVAC units. How is it helping today's technicians?

EW: Plug and play correlates to communicating system performance. Most 24-volt thermostats control operation in a manner like a light switch without a dimmer. It’s either on or off. That’s unfortunate. One of the challenges in delivering homeowner comfort is ever changing environmental conditions. One day it may be very hot and dry, other days may be cooler with some rain, and that single stage system cannot customize system operation to maximize homeowner comfort & efficiency through these wide range of conditions. With plug and play communication, the entire system can adjust speeds to maximize performance. The thermostat not only knows indoor temperature, but indoor relative humidity as well; and the homeowner can customize desired set points for temperature and humidity alike. On a hot summer day that requires a lot of sensible cooling capacity; the control system can ramp the compressor and blower to really focus on sensible capacity and keep the house cool. But on cooler rainy days, we tend to notice high indoor relatively humidity; which also tends to occur during the shoulder seasons of spring and fall. In these conditions, the communicating control system will reduce blower airflow to significantly improve dehumidification and maintain comfort. With over 750 compressor speeds; the plug and play control system continually adjusts compressor and blower speeds for what the environment requires at any given time.

Another challenge technicians face in the field is with control wiring. There are so many wires to be run, and various manufacturers may have different labeling. So, part of the Plug-and-Play with the Trane Link technology is consistency across all platforms: 4 wires, 24 volts in common and two communicating wires. So, whether it's a furnace, air handler air conditioner or heat pump, every system is wired the same. When you power it up, all components can "talk" to each other and configure the system automatically. Trane plug-and-play makes the technician’s life easier, and provides a better configuration experience for the homeowner.

We know that systems are becoming more complex and there’s a greater diversity from one manufacturer to another, so that a simple wiring diagram from 20 years ago, when I could walk up to almost any manufacturer’s unit, there was consistency between products. But with the increase of 2-stage unloading scroll and inverter systems, all of this is becoming more complex. And with the wide variety of units and controls from one manufacturer to another, field wiring for the technician is becoming more challenging. Our plug and play wiring strategy provides consistency within our communicating systems; making it easier for our technicians.

Trane has created a technician app that allows the tech to bring up data on the system they’re installing or servicing. For 24 volt installations, the technicians can scan the unit bar code or select the unit from a drop down menu and add accessories, such as a condensate switch or heat strips. The app will populate a point-to-point wiring diagram specific to the unit they are installing; making the installation easier from one product platform to another. For our Link communicating systems, the app provides configuration menus, test modes and monitor menus for system performance; all in the palm of your hand.

Also, our e-learning courses are seeing more gamification. The activities will offer full animation, where the technician can see inside the refrigerant system and duct system and see exactly what’s going on with system performance, then create field situational conditions the technician needs to solve on the computer; such as dragging wires to their proper location or adjusting refrigerant charge.

CB: How is Trane helping dealers remain up-to-speed related to A2L refrigerants?

EW: The transition to A2L refrigerants is an easier transition than we had going from R-22 to R-410A. That was a difficult challenge because of compressor oils, moisture concerns and higher operating pressures. With this transition, the R-454B refrigerant is very similar to R-410A. Refrigerant pressures and refrigerant oils are very similar.

A major difference is that A2L refrigerant is slightly flammable. So now, there are requirements for pressure tests. We always said, ‘pressurize line sets with nitrogen and make sure you have no leaks as a good practice.’ Now, we will say, ‘pressurize linesets to make sure you have no leaks for safety.’ So, it’s gone from a good practice to a requirement.

Any technician that has been following the good practices of the past will not see many changes in their day-to-day operation going forward. R-32’s pressures may be a little bit lower, and it tends to run a little hotter out of the discharge, so there are minor differences between R-32 and R-454B.

The transition should not be too painful for technicians who understand best refrigerant practices.

CB: What training has Trane made available for the refrigerant transition?

EW: Trane has developed a series of training sessions. There’s a one-hour online training for all Trane dealers that covers the A2L low GWP refrigerant transition.

Our Factory Service Representatives – we have about 250 in the US and Canada – are out there providing training. Dealers can view training online, or through several webinars I’ve put together on the subject. We also have a series of short videos that are narrowly focused on certain aspects of the A2L transition, such as control wiring or troubleshooting a refrigerant detection sensor. So it’s a combination of in-depth learning combined with short videos should make life easier for Trane field technicians.

CB: Earlier in 2024, Trane announced new product naming and tiering. How are technicians responding and how is Trane helping?

EW: We’ve transitioned from letters, such as "XR" for residential and "XB" for builders, and created terminology that is more intuitive. Now, we can have a Premier line or Choice line. That is a type of “good, better, best” strategy. From a sales perspective, it might be easier to align that, to say, ‘Here’s the platform, and the Premier system will be more complex. It will be like that LINK communicating system with the intelligence to maximize comfort and efficiency. Whereas a Choice system will be more of a simpler, cost-focused system at lower efficiency.

The pairing of this naming transition, which seems to be more intuitive alongside the refrigerant transition, coincides very nicely.