Two technical issues are at the top of the list in refrigerant world today: what are supermarket refrigeration customers to do with older, existing equipment, and what refrigerants are becoming preferred options for new equipment?

Andrew Pansulla, technical service engineer, the Chemours Company, says many of the conversations he and his colleagues are having with end-users, distributors and contractors fall into those two categories.

“There is an installed, aging base of equipment that’s using high Global Warming Potential (GWP) refrigerants, and inBut dialogue is good, and in the spirit of continual growth, Pansulla said people are constantly installing new equipment, and with some of the proposed regulations, they’re wondering if the refrigerants that are used for retrofits make sense. “Or they will ask about installing A2L refrigerant in new equipment. They may also ask if they have to do something off the cuff or different, like a cascade system or CO2. Those are the main questions we’re getting.”

A2Ls: New Equipment Only

Pansulla emphasized that contractors must know that A2L refrigerants – which have shaken up the refrigerant industry due to their “mildly flammable” classification – are to be used in new equipment only. A2Ls have been thoroughly tested and building codes are gradually being changed to allow for their use in public places.

A2Ls have been thoroughly tested and building codes are gradually being changed to allow for their use in public places.

”If you have a piece of equipment that’s reached the end of its useful life and is also using a high GWP refrigerant, you’re likely going to be looking at replacing it with an A2L system, based on the new safety standard designs,” PansullaAnswer Man

Pansulla is cool, calm and collected as he fields our questions. He’s answered many of them during his travel and phone discussions with many interest groups. He stated clearly that one of the goals the industry hopes to see is that end users “see no difference” in operation with the newer alternative refrigerants.

“The first thing I look at, because I think it is the most clear and concise, is the proposal for the technology transition rule.“One question I like to pose to end users is, let’s say there is a major leak and you lose the refrigerant charge. What will you do about that, understanding what your retrofit options are, the life of your equipment, what type of training contractors have and contractor availability? All of those play into the larger theme of understanding which refrigerants you want to use.

Pansulla added that Chemours is working to be certain refrigerant end users are aware of some of the retrofit gasses that are available, should they need to or want to move to lower GWP refrigerants, such as R-449A or R-513A. Those are good refrigerants to help transition to a more sustainable solution.

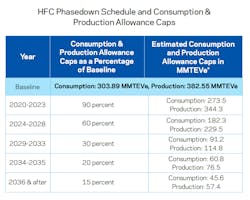

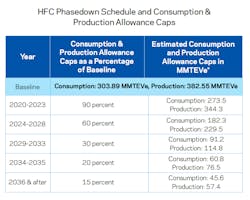

“One big thing we try to educate the industry on is R-404A. If you’re still installing R-404A I would strongly reconsider that, because if you look at how the AIM Act is structured, R-404A is not a long-term solution.

Reclaiming used refrigerant is a big piece of the transition puzzle, because not every older refrigerant will be gone anytime soon.

“In the contractor sector, the losers will be those who have not stockpiled and recycled and reclaimed used refrigerant," he warned.

Yes, contractors: reclaiming used refrigerant is a big piece of the transition puzzle, because not every older refrigerant will be gone anytime soon.

“Historically, when refrigerants were cheap and available, the reclaim option was always there,” Pansulla said, “but it wasn’t seen as a value-added piece of a business. Now, refrigerant reclaiming will play a big part in refrigerant management. Supermarkets will have 3000 pounds of refrigerant in their stores, and that’s an asset they can use to offset costs for future replacements, or as a service gas at other properties. There are several different ways you can use reclaimed refrigerant. That will be something everybody’s going to be asking about in the next couple of years,” Pansulla predicted.

Upgrading Systems: When and How?

What are the major considerations for knowing when and how to upgrade to new refrigerant systems?

“First and foremost, consider the age of the equipment. Equipment wasn’t designed to last forever. Mechanical things will wear out over time, and it’s important to know if it’s reached the end of its useful life,” Pansulla said. “Next, we’ve seen people try to prioritize those stores that are ‘leakers,’ and [for whatever reason] leak more refrigerant than others. Likely this is a good opportunity, using some of the regulations, to address those stores and button up the leaks, and possibly transition to another refrigerant if it is using something not as prevalent in the industry.

“Third, if you have a lot of certain refrigerants that are impacted by regulations, those are the ones it could make sense to proactively retrofit to create a reclaim source of gas that could be used for service or sold back to the market. I’d say those are probably the major considerations: age and condition. If the store systems are leaking and is using refrigerant is no longer used in new equipment.”

Seek Out Training

Education includes seeking out the best knowledge from leading resources.

“I can’t stress enough the importance of staying in tune with everything that’s going on, in the sense of proactively looking for training. Practically every OEM in the refrigeration industry, and Chemours, provides training programs in their different realms of knowledge. So there’s a lot of great information out there and people who would be happy to set up training classes with entire contracting companies to make sure people are using these products the way they are intended to be used,” Pansulla advised.

Pansulla is one of a team of Chemours training advisers who visit contractors, end users and original equipment manufacturers, “making sure they’re in touch with the ever-changing world of refrigerants. We’ll provide a half-day class, and an entire company will attend. We’ll go over regulations, R-22 retrofits and A2Ls. We provide those trainings directly with contractors as needed, and we have a strong presence with the training bodies that are out there such as ACCA or PHCC or HVAC Excellence. We go to the trade level and visit shops about using refrigerants correctly,” Pansulla shared.

“Having knowledge of what’s going on in the refrigerant world is knowledge that can set a contractor apart from their peers. It’s constantly changing, it’s important, and it needs to be done right the first time.”

Two Options for Retrofit and New Systems

“Chemours offers two zero-ODP, low-GWP refrigerants in our Opteon™ XP portfolio that are well suited for medium-temperature refrigeration," Andrew Pansulla explained. "Those are Opteon™ XP40 (R-449A) and XP10 (R-513A). Both refrigerants are ASHRAE A1, non-flammable refrigerants, designed for applications that require use of a non-flammable refrigerant, such as a retrofit application. One of the primary goals of these refrigerants is to extend the life of existing equipment designed to operate with an incumbent HFC or HCFC. While alternatives with lower GWPs will come into the market, these refrigerants will continue to be very important to a larger refrigerant management plan. This is because there are limited other products readily available that can meet or exceed the performance of an incumbent system design while utilizing a nonflammable refrigerant.

“Opteon™ XL products are zero-ODP, low-GWP mildly flammable refrigerants. The portfolio includes: XL10 (R-1234yf), XL20 (R-454C) and XL40 (R-454A) for refrigeration and Opteon™ XL41 (R-454B) for air conditioning. All Opteon™ XL refrigerants are A2L, mildly flammable refrigerants, for new equipment only, not retrofits."

(Photo of refrigeration rack if it fits)

About the Author

Terry McIver

Content Director - CB

As director of content for Contracting Business, he produces daily content and feature articles for CB's 38,000 print subscribers and many more Internet visitors. He has written hundreds, if not two or three, pieces of news, features and contractor profile articles for CB's audience of quality HVACR contractors. He can also be found covering HVACR industry events or visiting with manufacturers and contractors. He also has significant experience in trade show planning.