Latest from Residential HVAC

The Art of Residential HVAC Commissioning

HVAC commissioning is usually a testing and reporting process that takes place at the end of an HVAC system installation. It documents the system was installed according to designer’s and manufacturer’s requirements.

Long Term Benefits

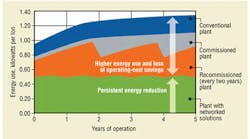

The residential commissioning process revolves around the measurement and verification of the performance of an HVAC system. The benefits of this process continue past startup and can become a baseline that will be referred back to each time the system is serviced.

Consider Offering Commissioning Options.

An HVAC residential system commissioning process should be adaptable to the needs and budget of customers. Consider offering several levels of commissioning that deliver a level of quality assurance your customers may be willing to invest in.

Here is a list of services to use to develop your commissioning packages:

• assessing your customer’s needs

• designing for optimized results

• installation is completed according to all performance specifications

• the system is tested and balanced

• refrigerant and combustion are measured and adjusted

• rating the performance of the HVAC system

• safety assurance via inspection and CO testing

• the building’s performance is verified.

Assessing Customer Needs

Not every customer may desire to include commissioning as part of their new construction or retrofit job. Most of us have learned that some customers just want cheap. Commissioning isn’t about cheap.

During the interview, before the sale is made, effective salespeople or selling technicians discuss options and benefits that may be appealing to customers. Offering a list of commissioning services and benefits will help you and your customer better understand what level of quality they’re looking for.

Your customer’s desire to purchase any of the commissioning services will take the discussion far beyond the equipment and into comfort, efficiency, and other issues they’d like solved at the same time equipment is replaced. Diagnostic testing will also identify many of these issues for your customer and prove you can solve their problems.

Designing for Optimum Results

Most companies have different levels of design methods based on the quality of the job. Low-cost design methods begin with the installers designing the system during the installation. Unfortunately, this design method often ends up producing poorly performing systems.

The next step up may include a manufacturer’s load calculation and a duct schematic. Better service companies may deliver ACCA Manual J, D, S, and T Documentation for an increased fee. The best contractors will provide an air test and balance report, proving the system was installed and is delivering the performance as promised.

Installation Follows Specifications. A design without installation specifications is assuming the outcome will match design. When a job is handed off to the installers, a design should include specifications the installer can follow during installation.

Your company installation specifications can be as simple as a standard set of company procedures that can be applied universally to all installations. Such specifications can also extend to a list of detailed instructions for each job. These instructions need to address unique installation conditions and any special requirements for that job.

Industry standards — although often difficult to apply directly in the field — can be summarized and taught to your installation crews. Equipment specifications also contain requirements the installers must follow to assure adequate system performance.

An effective commissioning process compares the design and specifications to the installed system. It also includes documentation of discrepancies and recommended repairs critical to the performance of the system.

Testing and Balancing. In addition to setting fan airflow to the required cfm at each register and grille, air balancing contains several other tests to reinforce airflow measurements and assure the equipment and system are performing to design as well as manufacturer specifications.

These include the measurement of the system’s total external static pressure and the pressure drops over the filter, coil, and the supply and return duct system. System temperatures entering and exiting the equipment and the system are also measured/recorded. Wet bulb temperature readings are taken when the system is operating in cooling mode. Plus, voltage, amp draw, and fan RPM (if accessible) are measured/recorded.

For the past 20 years residential air balancing has been the preferred method of verification for the HVAC industry. Your customers will recognize its value when it comes to individual room comfort and in the extended life of their new equipment.

Refrigerant & Combustion Testing

Once system airflow has been balanced and verified, the next step is to measure, adjust, and optimize the refrigerant charge for cooling months and gas-combustion furnaces in the heating months.

On the refrigerant side, each manufacturer provides specific charging data specific to each piece of equipment. Be sure to refer to each manufacturer’s specifications; don’t use generic subcooling methods. These never produce well-performing cooling systems and can often deteriorate performance in excess of 20%.

The goals of accurate combustion testing and adjustment is simply to measure the elements of combustion and make needed adjustments to assure the equipment output matches the manufacturer’s published BTU output.

Many assume gas and oil furnaces are magically tuned at the factory and equipment performance automatically matches output on the nameplate data. It doesn’t. Unfortunately, until you measure, you’re only guessing.

Verifying refrigerant charge and combustion efficiency are valuable services that may be included in your list of commissioning services. Remember, verifying airflow alone doesn’t assure performance or efficiency by itself.

Rating System Performance

The crowning jewel of a commissioning report is the rating of the HVAC system performance.

At this point, since the system airflow and temperatures are already measured and recorded, all that’s left is to apply the heating and cooling BTU formulas to determine actual delivered BTU of the equipment and system.

Basically, the performance of the system can be rated by dividing delivered BTU into the equipment rated BTU to express system performance in a ratio or a percentage of performance. This performance rating summarizes the report and the result of your commissioning. It also establishes the value of commissioning to your customer.

One added touch is to use the airflow and system temperature gathered before the commissioning, and calculate a before-and-after commissioning performance rating. This calculation separates the men from the boys.

Safety Inspection and Testing

One final option to include in all commissioning options is safety inspection and testing. Every customer cares about and expects safety. Include safety in all your commissioning reports.

A brief inspection of the system’s electrical components — including wiring, motors, grounding and disconnects — will cover your bases in just a few minutes. Measure amperage and voltage, then compare to specification.

Note any code violations or unsafe conditions and recommend repairs in your commissioning report. If commissioning for your own company, give the installers a heads up so the problems can be fixed before they are mentioned in the final report. Inspect, measure, and adjust the venting systems under a variety of conditions and assure venting is safe and functional.

Last but not least, measure for ambient carbon monoxide (CO) levels and CO levels at the equipment during operation. Compare them to accepted industry standards. Air Balancing assures comfort, CO testing saves lives.

Buildings Performance is Verified. More HVAC companies are taking responsibility for the building as a part of the duct system. The building is what the system airflow passes through as it leaves the supply registers and enters the return grilles. The building envelope can be claimed and improved by HVAC service companies when explained to your customers this way.

Assuring that the building envelope’s performance matches the performance of your HVAC system adds value to the job and a commissioning report. An inspection accompanied by an infrared camera reveals obvious building defects. A blower door test compares envelope leakage to published industry standards, and often takes very little work to improve to an acceptable level.

Performance Baseline

Once the installation and commissioning is complete, the data collected during commissioning can be referred to throughout the life of the system whenever the system is maintained or serviced.

Create a sticker that can be affixed permanently to the equipment where key performance measurements can be recorded and referred to by a service tech.

Commissioning Benefits All

First, your customer and then you, the installing contractor, will benefit from commissioning as described throughout this article. Manufactures also will benefit from reduced warranty costs associated with a poorly performing installation.

Everyone wins when a residential system is properly commissioned.

Rob “Doc” Falke and John Puryear serve the industry through National Comfort Institute — an HVAC-based training company and membership organization. If you’re an HVAC contractor or technician interested in a free procedure showing how to measure system delivered BTU, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles, and downloads.