Improper charge is the biggest non-electrical cause of callbacks on a fixed restrictor air conditioning system. If all components are functioning properly, the best way to avoid improper charge on such systems is to compare actual superheat to target superheat.

Superheat is a temperature rise above the saturation (boiling) temperature of a substance for a given pressure. If heat is added to refrigerant when it’s a 100% saturated vapor, it will become superheated.

To understand superheat, imagine a pressure cooker full of water and steam. As heat is continually added to the water, the water evaporates into steam. While it does this at a constant pressure, the environment in the pot will remain at the same temperature: the energy from the heat goes into turning the water into steam. Once all of the water becomes steam, additional energy (heat) introduced into the pot will cause a rise in temperature. This temperature rise above the saturation temperature (boiling point) for that constant pressure is called superheat.

Superheat in Action

Actual superheat is calculated from your suction line pressure and temperature measurements.

The formula is:

suction line temperature – suction line saturation (boiling) temperature = actual superheat

A properly charged, fixed restrictor air conditioner has an actual superheat that matches the target superheat for the current outdoor and indoor environmental conditions. Adjusting the actual superheat in a fixed restrictor system can be done by adding or recovering refrigerant (for systems equipped with a thermostatic or electronic expansion valve, see the sidebar at lower left).

Superheat is an essential safety measure to ensure that liquid refrigerant never enters the compressor. All compressors are designed to compress vapor refrigerant. Various compressor types and brands have different tolerances to liquid exposure, but one thing is certain: they’ll a fail prematurely if they’re exposed to liquid refrigerant for an extended period of time.

Too much superheat reduces the real world cooling capacity of a system (tonnage). To maximize the capacity of an indoor evaporator coil you would want 0F of superheat and a 100% saturated vapor right at the exit of the evaporator coil. This would allow for the greatest cooling potential of the coil, because the coil absorbs much more heat from the air in turning the liquid refrigerant into vapor than it does in superheating the refrigerant. However, this would put your compressor in great risk for premature failure because it leaves you with an unknown and minimal margin of safety. If you charged a system this way, a change in the indoor or outdoor environment or suction line pressure would expose the compressor to liquid refrigerant. Too much superheat could also affect compressor cooling, since refrigerant is used for heat dissipation of the compressor.

Target Superheat

Target superheat is the recommended superheat for the given indoor and outdoor environmental conditions.

Environmental conditions affect the amount of actual superheat found in a system. For that reason, the target superheat chart of a system must take into account all the environmental conditions under which the system is expected to run. This ensures that even if the environmental conditions change, the system will operate with good capacity and the compressor will not be exposed to liquid refrigerant.

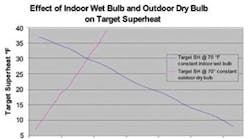

Most target superheat charts require indoor wet bulb and outdoor dry bulb measurements to yield a target superheat.

Chart Properties Inside and Out

Target superheat tables all have limits for the maximum and minimum outdoor dry bulb and indoor wet bulb temperatures used to obtain a target superheat. If you’re outside of these ranges, you won’t be able to properly charge the air conditioning system using these tables. These tables were developed to accommodate the most typical operating ranges of the air conditioning equipment as specified by the manufacturers of the equipment.

The minimum recommended target superheat for most charts is between 4F to 5F for the environments with low indoor wet bulb and high outdoor dry bulb. Table 1 shows the effects of a changing indoor wet bulb and an outdoor dry bulb on target superheat. The target superheat increases rapidly with an increase in indoor wet bulb, and decreases slowly with an increase in outdoor dry bulb.

The relative humidity of the indoor air plays a very large role in where in the evaporator the refrigerant begins to become superheated. In order for target superheat charts to be accurate, they must take indoor relative humidity (RH) into account. This is most commonly done by taking indoor wet bulb measurements.

When 50% RH for the indoor conditions is assumed, the effect of changing indoor heat load is not properly taken into account, and the resulting target superheats will not be accurate. If you charge assuming 50% RH, you could either put the compressor in danger for those times when the air conditioner has been on long enough to have a low indoor load relative to the outdoor load, or you could reduce the system’s capacity during the most commonly operated conditions.

The outdoor conditions may not change between measurements, but because you are cooling and dehumidifying the inside, the indoor conditions do. As the air conditioner cools the indoor air, the indoor heat load decreases. This causes the actual and target superheat to decrease. It’s important to verify the actual superheat and target superheat at the same time to prevent changing conditions from affecting your refrigerant charging procedure.

The temperature of the outside air also has a great effect on how much heat can effectively transfer to the outdoor environment. The hotter it is outside, the harder it is for the condenser to dump heat into the outside ambient. This reduces the capacity of an air conditioning system. In fact air conditioning units are only specified to run up to a certain outside ambient temperature. Because there’s no change to the moisture level of the air going through a condenser, only outdoor dry bulb measurements are necessary to assess the outdoor heat load.

Taking the Measurements

Target superheat charts usually require indoor wet bulb and outdoor dry bulb measurements. These measurements are really concerned with the air traveling over the evaporator coil and condenser coil, respectively. This air is the actual environment that the refrigerant coils are exposed to, and taking these measurements accurately without interfering with the normal operation of the air conditioning system can be tricky.

Take indoor wet bulb temperature measurements as close to the inlet of the evaporator coil as possible. In many cases there is an air filter before the evaporator onto which a wet bulb thermocouple can be clipped. Take the measurement as close to the center of the air stream as possible. The system must be sealed as it is during normal operation when the measurements are taken (Figure 1). If there is no filter in front of the evaporator, a small hole can be made before the evaporator. Make sure you don’t damage any equipment when doing this, and that you seal the hole once you have finished.

Some technicians use other measurements, such as return air grille temperatures, to determine indoor wet bulb. However, because there are temperature changes and infiltration of outside air on the return air duct before it arrives at the evaporator, using these measurements for target superheat will not give you the best accuracy. The best measurement is taken right before the evaporator.

For best accuracy, take the outdoor dry bulb temperature in the center of the inlet fins. Clipping a thermocouple to the fins themselves makes the measurement very convenient and repeatable.

Actual superheat requires that you measure the temperature and saturation temperature (boiling point) of the refrigerant in the suction line. The saturation temperature is traditionally found on a pressure/temperature chart for a measured pressure, or could be right on the gauge along with the pressure reading. Because pressure drops occur throughout the refrigerant lines, taking the temperature and pressure measurements physically close to each other will minimize errors. Typically, both of these measurements are taken near the suction side service port (Figure 2).

For best results when measuring suction line temperature, use a probe that’s specifically designed to take the temperatures of refrigerant pipes. A probe that doesn’t make good thermal contact with the refrigerant pipes, or one that doesn’t keep that temperature effectively isolated from the ambient environment, will give you false pipe temperatures which could lead to improper charging. Select a thermometer that is specifically designed for measuring pipe temperatures, and use it on every service call you make.

Try to expose as little of the refrigerant piping as possible to the ambient air to accurately represent how the system will be running when you’re not there. Place the sensor of the suction line thermometer close to the horizontal center line of the pipe to avoid taking the temperature of refrigerant oils or noncondensables which may be present in the line (Figure 3).

The saturation temperature (boiling point) in the suction line is looked up from the type of refrigerant and the pressure measured at the suction line service port. Many gauges actually have the saturation temperature for one or two refrigerants printed right on the dial of the gauge. If you’re working on a refrigerant whose saturation temperature does not appear directly on the pressure gauge, a pressure/temperature chart can be used to find the saturation temperature based on measured pressure and the type of refrigerant.

Automating the Process

There are several instruments for automating the tedious process of getting the measurements for target and actual superheat and then performing the calculations. Most superheat instruments automate the process of getting the actual superheat. Whichever instruments you choose, make sure the sensors and instruments are specifically designed for your application.

There are also a few products that automate the target and actual superheat measurement process and entire superheat diagnosis process as a whole. Some of these instruments are field upgradeable and contain charts that go beyond the typical target superheat charts, allowing for charging air conditioners in preventive maintenance or for very hot climates. Some of these instruments will even alert you to unusual conditions and possible measurement errors prompting you to retake the measurements. These instruments are great time savers and also can be used as training tools.

Adolfo Wurts is engineering manager for Fieldpiece Instruments, Anaheim, CA. He can be reached at 714/634-1844, or by e-mail to [email protected].

| SUPERHEAT AND TXV/EXV SYSTEMS Thermal expansion valves (TXVs) and electronic expansion valves (EXVs) are designed to maintain constant superheat despite a change in indoor or outdoor environmental conditions. In systems equipped with these valves, the subcooling in the air conditioning system changes with the environmental conditions while the superheat stays constant. Because TXV/EXV systems have greater variety in their designs, manufacturer’s target subcooling should be used to determine the proper charge level for a TXV/EXV system whenever possible. An actual superheat measurement can be used with a TXV/EXV system to check performance of the TXV/EXV valve. — AW |