Unlocking System Performance Potential: The Domino Effect of Static Pressure Testing

Static pressure imbalances keep many HVAC systems from reaching their highest efficiency. Most residential air handling equipment operates with a maximum total external static pressure (TESP) of 0.50 inches water column (in. w.c.). Unfortunately, many operate at around 0.82 in. w.c. or worse, putting a strain on the system. This results in higher operational costs and decreased comfort.

As an HVAC professional, you have a vital role in accurate pressure assessments. These are necessary to maintain and enhance system performance. Let’s look at the effect static pressure has on maintenance and potential high TESP solutions.

Unraveling the Impact of the Domino Effect on HVAC Maintenance

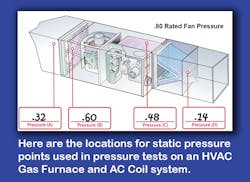

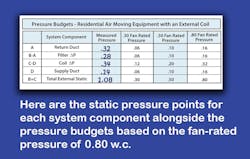

Static pressure testing helps HVAC professionals understand airflow problems. This data empowers you to make decisions based on installation conditions. With proper training, you can take the proper steps to make the right repairs and adjustments.

Picture a scenario where a pressure assessment uncovers high static pressure, showing restricted airflow, undersized ducts, restrictive filters, dirty blowers, and dirty coils. We can restore balance and optimize performance by identifying the root causes and implementing corrective measures.

Issues that contribute higher-than-normal static pressure include:

- Undersized ducts

- Restrictive filters

- Dirty blowers or coils.

To fix this and make the system work better, you need to find the root causes and make changes like:

- Resize the ducts

- Use less restrictive filters

- Clean the blowers and coils.

These fixes address the immediate problem and help the system last longer and work more reliably.

If you ignore pressure issues, they can cause many other problems. Again, high pressure causes the system to use more energy, poor airflow, and increased wear and tear on parts. This leads to more customer complaints.

By understanding the pressure tests and taking action, you can avoid these problems. Regular maintenance can keep the system fine-tuned. This saves money in the long run and keeps the occupants comfortable. A proactive approach like this is better than fixing problems when they happen.

Preventative Actions and Lasting Effects

Preventive maintenance is crucial for HVAC contractors to ensure optimal system performance. Regular testing and maintenance prevent issues and maximize system operation.

Integrating static pressure testing into your regular maintenance routines enables you to spot emerging problems before they cause significant disruptions in the system.

Addressing maintenance issues proactively prevents the domino effect of problems that result from neglect. Cleaning coils, checking system refrigerant levels, and lubricating moving parts can improve performance and extend the system’s lifespan.

HVAC companies can earn their customers’ trust by taking steps that lower repair costs and improve home comfort. Talk to them about the importance of regular static pressure tests and preventive maintenance. This distinguishes your services and fosters lasting customer relationships.

Interventions That Are Targeted and Specific

You can improve system performance using pressure assessment data and these targeted interventions.

- Duct Resizing: If the pressure assessment shows undersized ducts as the issue, it is advisable to resize the ducts. Increasing duct size can enhance airflow and reduce pressure drop. Resizing the ductwork can ease the strain on the system and restore proper airflow.

- Duct Sealing: Pressure tests show air leaks in the ducts. These leaks cause uneven air pressure, which makes the HVAC system less efficient. Sealing the ducts eliminates the leaks and

- Register & Grille Upgrade: Upgrading the air vents and grilles is essential if the airflow is uneven and does not reach every room. In many homes, the standard air vents and grilles don’t direct the airflow as well as they should. Upgrading to better-designed vents and grilles will help the air reach every room and improve the comfort of the people living in the home. It’s not a luxury and getting the most out of your home’s heating and cooling system is necessary.

- Air Filter Replacement: A dirty or clogged air filter can cause problems for your HVAC system. It creates high air pressure, which makes the blower motor work harder. This reduces the system’s efficiency. By looking at the air pressure data, you can tell if the air filter needs to be replaced. Swapping it out with a clean filter of the right size and efficiency rating will fix the issue. Using the right air filter ensures proper airflow. This prevents strain on the HVAC system and helps it operate at its best. So, if you notice the air filter is dirty, replace it with a clean one

- Fan Speed Adjustment: Incorrectly set fan speeds can cause high static pressure in certain situations. The pressure assessment data allows you to decide if adjusting the fan speed is necessary to achieve optimal airflow. Changing the fan speed can alleviate pressure imbalances and enhance system performance.

- Equipment Commissioning: HVAC equipment performance can be evaluated through pressure assessments during commissioning, which can uncover problems such as incorrect refrigerant charge or improper blower motor speed settings. Based on the commissioning data, you can calibrate the equipment to ensure it operates within the manufacturer’s specifications, optimizing system efficiency and performance.

- Duct Insulation: While not part of a pressure assessment, installation of duct insulation may be advised. Insulating the ducts minimizes energy losses and helps maintain the desired temperature throughout the system. Implementing this intervention can increase overall system efficiency and decrease energy consumption.

The work of HVAC professionals is crucial for energy conservation and comfort. Your job is more important than ever before in this regard. You can enhance things promptly through precise and thorough testing, then using the results to implement changes. Those changes can continue to help for a long time.

The HVAC industry is advancing its technology. To keep up, we need to constantly improve HVAC efficiency to match technological progress in the field. The key to this is doing thorough air pressure checks. The outcomes may set off a domino effect of favorable adjustments. These adjustments will improve the HVAC system’s performance and prolong client satisfaction. This helps both now and in the future.

Rob Minnick is an instructor at National Comfort Institute NCI. He has 44 years’ experience in the HVAC Industry with his family’s business as well as 14 years teaching and training contractors on how to overcome obstacles and be more successful. He can be reached at ncilink.com/Contact Me.

About the Author

Rob Minnick

Certified HVAC Trainer

National Comfort Institute trainer Rob Minnick is a former HVAC contractor with 43 years of experience in the Heating and Air Conditioning field, particularly with Mechanical Design & Building Performance for owners.

He earned his certifications from the State of Maryland, Air Conditioning Contractors of America, Building Performance Institute, Residential Energy Service Network, United States Green Building Council, and National Comfort Institute.

Rob is active in many associations, including ACCA National Products & QA Committee Chair, ACCA/BPI QEE Standard Development Committee, Building Performance Institute (BPI), Building Performance Association, Building Performance Association National Program Committee, ACHR News Advisory Board, HVACRedu.net Program Oversight Committee, Home Energy Magazine's Editorial Advisory Board, and Maryland Youth Apprenticeship Advisory Committee.