In this 13 SEER world, thermostatic expansion valves (often referred to as TEVs or TXVs) are playing a larger role than ever before. These cooling system components have a profound effect on coil and overall system efficiency.

TEVs, like fixed metering devices, serve to control refrigerant delivery to the system. Metering devices have a direct effect on making cooling possible, through two very important processes: (1) lowering liquid line refrigerant pressure and (2) controlling the flow of refrigerant into the evaporator. TEVs are designed to accomplish these two tasks better than fixed-orifice metering devices because of their enhanced precision. They also offer tight control over superheat and are highly reliable.

TEVs Gain Importance in 13 SEER World

TEVs have been around for about 30 years, but the advent of the 13 SEER minimum efficiency standard has given them their day in the sun.

Before 13 SEER, when system capacity was more important than system efficiency, the traditionally used, fixed-metering system was sufficient. Now, TEVs help systems more effectively and easily reach 13 SEER minimums because they help make refrigerant flow more precise. In fact, many manufacturers have a full array of coils that include factory-installed TEVs or upgrade kits.

TEVs have excellent reliability, and new coils are TEV-equipped when they leave the factory. Proponents of TEVs say they offer many benefits over fixed metering devices, including:

- better evaporator control

- higher equipment efficiency

- higher equipment reliability.

Some technicians still harbor misunderstandings about TEV-equipped systems, often due to a general unfamiliarity with them. However, with today's technology, TEVs have become more accepted as mainstream. Think back to older thermostats and compare them to the programmable thermostats of today. Early on, many were apprehensive about the new thermostats; now they are mainstream. As technicians routinely encounter TEVs and become more familiar with what they do and how they do it, TEVs will become even more widely recognized as the vital component they are in the 13 SEER marketplace.

Diagnosis and Troubleshooting

TEVs have few moving parts, and are normally very reliable. However, if a TEV fails, proper diagnosis and troubleshooting are critical to evaluate its functionality.

Despite their high reliability, there are times when TEVs can be the source of a problem in an air conditioning system. These include when:

- the TEV powerhead fails

- the TEV does not match the unit

- the TEV thermal bulb is poorly mounted

- a refrigerant circuit is contaminated.

Before spending a lot of time checking the TEV in superheat situations, make sure the system is correctly charged. Many factors other than the TEV can affect superheat.

To quickly check a TEV, remove the bulb from the suction line mounting and heat it with warm water, or your hand. Once the bulb is warmed — which falsely causes the TEV to sense warmth and high superheat — the valve should open and flood the evaporator with refrigerant. Suction pressure should rise. The TEV is not controlling flow during this test. Liquid floodback is highly likely if the test takes more than 30 seconds.

A more accurate test can be done on a TEV using a combination of the warming test and a temperature sensor taped to the suction line at the evaporator outlet. When performing this test, make sure to insulate the sensor connection.

By warming the bulb, port opening, the suction line temperature, and superheat to match design conditions, you know the TEV is good if it opens. It's also a good idea to check the capillary tube, since a ruptured tube can lead to lost refrigerant in the bulb.

Sizing and Selecting a TEV

Sizing and selecting TEVs, particularly in newer, more efficient units, must be done carefully to ensure they match the system's many operating conditions. This sizing is important because of fundamental differences between refrigerant flow rates and superheat settings from one TEV to another. Also, TEVs are not interchangeable from R-22 to R-410A equipment.

Oversized TEVs often cause " hunting," which occurs when the superheat rises and falls erratically and doesn't settle on one setting. When a TEV is oversized, it will flood too much refrigerant into the evaporator when the port opens, resulting in rapidly dropping superheat levels.

Installation Tips

A correctly operating sensing bulb is critical for precise operation of a TEV. The bulb must properly measure suction line temperature for the powerhead to accurately calculate suction gas superheat.

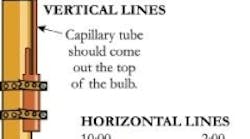

Clamp the bulb securely to the suction line at a straight and clean section of tubing to get reliable thermal transfer from the tubing to the bulb. Insulate the bulb to prevent ambient effects on it.

When replacing the TEV, use the manufacturer's recommended part number — don't automatically assume that the one being replaced is the correct TEV for the unit, as an incorrect valve may have been previously installed.

Many TEVs are brazed into the system. If brazing is necessary, be careful not to overheat the valve, as TEVs are built to tight mechanical tolerances. Overheating can cause sticking of machined parts and unit failure. To prevent overheating, use a commercially available heat barrier compound or wet cloth, and direct brazing flame away from valve. The capillary tube is sensitive and vulnerable to abuse if care is not exercised in installation.

A Great Opportunity

A TEV is one of the most reliable components available for today's higher-efficiency systems. It can control superheat, which is one of the most important system conditions to achieving and maintaining peak design efficiency and reliability.

Contractors who don't quickly become familiar and comfortable with TEVs risk missing a great opportunity to satisfy customers and build a profitable business in this 13 SEER world. Make TEV training an integral part of your efforts to stay current with this important part of today's home comfort systems.

Greg Parks is a district technical representative for Rheem Air Conditioning Division. He provides onsite system inspections, troubleshooting, and technical training for Rheem and Ruud distributors and contractors throughout his territory of New Mexico, Texas, and southern Louisiana. Parks can be reached at 806/783-8702, e-mail [email protected]