Latest from Service

Fan motors are the unsung “heart” of HVAC equipment. They work unobtrusively and quietly for years, often under tough conditions. They don’t need a lot of love, but they do need periodic attention and it’s up to you to provide it. The cost of overlooking regular testing and maintenance of motors can be an HVAC system that grinds to a halt, so be sure to check the motor on every maintenance and service call.

Check the Power and Windings

When you arrive on a jobsite in which a unit’s fan motor is not working or the high-limit switch has tripped, the first thing to check is power to the motor and/or unit. If there is proper voltage, check the low-voltage control circuit. Check for proper voltage at the transformer and check for a fuse in the low-voltage circuit. Make sure the circuit breaker is not tripped (or the fuse is not blown). If the circuit breaker is tripped (or fuse is blown) or if the transformer is bad, it could indicate a short in the motor. In that case, check the windings in the motor before turning the power back on.

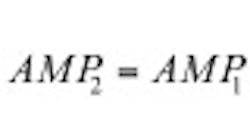

To check the windings of a motor for an open or a short, you’ll need to measure the ohms. If the unit has a 120V motor, it will most likely have three or four colored wires (black, red, yellow, and blue are common), a white wire, and two brown wires. Do a resistance check between the white wire and each of the colored wires. The higher the resistance, the lower the speed, with each color representing a different speed: i.e., four colored wires, 4-speed; three colored wires, 3-speed.

You want to see a resistance reading. If you get a zero reading that means the motor winding is shorted and may be the cause of the tripped breaker/blown fuse. If you get an infinite reading (overlimit or OL on most digital meters), that indicates an open motor winding. If either of these conditions exist you will have to replace the motor.

When checking the ohms on motor windings, many technicians have difficulty determining an open winding vs. a shorted winding. But it’s really not hard to tell the difference between the two. Read the ohmmeter. It should show a resistance. If it shows a zero reading it probably means the windings are shorted out. If it shows an infinite reading, that means the windings are likely broken or open.

A good trick to remember this is that an infinite reading means the greatest resistance in the world. It’s like an open door leading to infinity — in other words, an open winding. Meanwhile, a zero reading means the load is taking a short cut around it — in other words, a short. That’s just a simple trick to help you remember that a zero reading means a short, and an infinite reading means an open or broken winding.

Don’t Overlook the Capacitor

Just because a motor is not running doesn’t mean the motor is bad. If the power is correct and the motor is neither shorted nor open, check the capacitor (that’s where the two brown wires go). A capacitor helps the motor run and gives it more torque. If a motor doesn’t have the torque to turn the blower wheel or the fan belt, it won’t start. So the capacitor plays a big role. The capacitors on most of residential blower motors are very small, so technicians tend to overlook them.

You should discharge the capacitor before handling it. Using a capacitor tester, make sure the microfarad reading is within 10% of the rated capacitance on the capacitor. It will be a number listed in uF or mfd, depending on the manufacturer. If the reading does not match the rating, replace the capacitor.

Checking 240V motors is slightly different because you will have two hot wires and most will be only single-speed. But you still ohm-out the windings to check for open and shorted windings and check the capacitor the same way.

Keep it Clean

Finally, when doing a routine maintenance call on a unit, always check and clean the motor. One of the biggest problems with motor burnouts is dirt. The main thing to tell homeowners is to keep everything clean. Most of the furnaces in heating climates are located in a laundry room or a basement. In those rooms, lint and dirt kicking up from inside the house can block the motor holes and make a motor overheat. When motors overheat they burn up their windings and bearings. So a lot of bad things can be caused by dirt. Remind customers that not getting their furnace cleaned annually could void the warranty.

Phil Rizzo is an HVAC instructor at Coyne College, Chicago, IL. He can be reached by email at [email protected].