Have you ever installed a system that suffered from low airflow and no matter what you did to try to fix it, the solution eluded you? The odds are the cause is invisible system defect where air gets trapped near the fan. Such defects are difficult to measure. Let's take a look at these unseen air challenges that can reduce fan airflow.

An Air Trap?

Yeah, an air trap. Contrary to what you may imagine, airflow does not move through ducting and fans following the nice straight little lines we draw on our duct schematics. It squishes and squirts and tumbles through fans and ducts in a most disorderly fashion as it meets a host of intended and unintended obstacles on its way through your systems.

Air traps are areas where air turbulence becomes so hostile that the air actually blocks its own forward motion. This blockage reduces fan and system airflow and often is invisible to static pressure readings and typical diagnostics at the point where the turbulences appear. So becoming aware they exist may be your only clue to solve the problems they create.

Air is a Fluid

To help visualize this phenomenon, recognize that air is heavy and that it moves similarly to how water moves through a system. A well-operating 5-ton residential fan moves 9,000 pounds of air per hour through your systems. Now, imagine fans pushing and pulling all that mass through your duct systems.

Now you can see that any fitting, transition, elbow, or sharp change in air direction through the system will have a much greater impact on airflow and fan performance than if air weighed nothing at all.

Fan Inlet Conditions

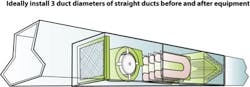

When fans are tested and fan performance tables are created in the laboratory, conditions are ideal. Typically, three or more fan inlet diameters of straight duct are installed directing airflow precisely into the fan to achieve the optimum performance possible.

Ideally, you would have similar conditions under which to install each fan in the systems you build. When possible, design and install lengthy fan intake ducts into fans.

Unfortunately reality dictates basements, attics, and pixie-sized mechanical rooms as the new dwelling place for most equipment. In these tight spaces, three straight duct diameters entering the fan just isn't going to happen.

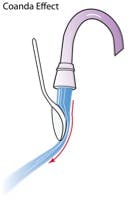

One solution you can build into almost any system where an elbow is near the fan inlet is to install a rounded throat into the elbow. This applies a trick called the Coanda effect that feeds the air more evenly into the fan intake.

To solve air trap issues near fans on your retrofit jobs, first solve static pressure issues in the duct system, filters and coils, and then renovate the duct system to increase the straight duct run feeding airflow into the fan. You may also install filters farther upstream of the equipment to improve fan inlet conditions.

Fan Discharge Conditions

Airflow loves a straight run out of the fan to gain momentum before being diffused every which way through the duct system.

When air leaves the fan, ideally three duct diameters (a duct diameter is three times the horizontal dimension of the fan discharge opening in the equipment cabinet) of straight duct are provided downstream of the fan.

Short basement installations are the curse of many equipment installations. A stubby bullhead tee is one sure way to assure airflow rarely exceeds 300 CFM per ton.

If you suffer from this symptom in your market, a few ways to improve fan airflow by renovating systems may be to:

- Change from upflow to horizontal equipment installations where room for lengthy fan inlet and discharge ducting can be provided.

- Select shorter furnaces or air handlers that leave room for longer fan discharge fittings.

- Install turning vanes in discharge fittings to guide airflow evenly out of fans. For residential systems be sure to use single-wall turning vanes to reduce fan discharge static pressures.

Don't Forget to Measure

Even a caveman can imagine perfect airflow. Many of us did it perfectly for years. However the day you begin to measure and verify the operation of your systems you'll find your knuckles no longer drag in the dirt and the size of your forehead will decrease significantly. You'll feel like you just discovered fire for the first time.

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC based training company and membership organization. If you're an HVAC contractor or technician interested in a free report on renovating duct systems, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles, and downloads.