Cost + overhead + a fair profit is the basic formula used by the HVAC industry to determine the price of a typical repair or equipment replacement. The net result of this practice is an average company net profit of 2% to 3% year-after-year. Let’s take a look at what some companies have learned to do to earn profits on some of their work that is ten times the industry average. First, a parable:

Tesla, Ford and the Boiler

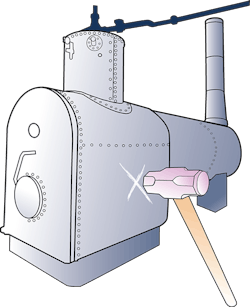

Henry Ford was having problems with a boiler in his Ford plant one day. Production stopped and dozens of workers sat idle. Nikola Tesla was called in to solve the problem. He walked up to the boiler, placed a small chalk “X” on its side, and whacked it with a small sledge hammer. The boiler fired and the plant resumed productivity. Ford expressed his gratitude and told Tesla to send an invoice.

A few days later the invoice arrived for $10,000.00. Ford, astonished at the amount, asked Tesla to itemize the invoice. A new invoice arrived: “Whacking the boiler with a hammer: $1.00, knowing where to whack the boiler with the hammer: $9,999.00.” Ford paid the invoice in full.

The point of the story is that Tesla sold his knowledge for what it was worth and his customer was willing to pay for it because the result delivered was worth the cost.

In our industry, we often can’t see the forest for the trees. We are often so immersed in what we are used to doing from day-to-day that we fail to realize the worth of the solutions and comfort we deliver to our customers.

As evidenced by our year-to-year profits, many of us believe our work is only worth a 3% profit.

How to Charge Like Tesla

Before Tesla arrived at the Ford factory, dozens tried to fix the boiler and had failed. So the stage was set for him.

In your job, how often do you arrive on the scene to find your customers suffering with a comfort or efficiency problem that others may have overlooked or attempted to fix and failed to provide a satisfactory solution? I’ll bet more often than not.

Tesla had knowledge and abilities the others did not possess. To be paid like Tesla, you must also have knowledge and abilities that others don’t. You need to arrive equipped to identify and solve problems others cannot.

The reality is that most HVAC systems have significant comfort and efficiency problems that are invisible to your competition. Providing solutions to these unseen and hard-to-identify problems is where Tesla-like profits can become available to you. But this can’t happen until you are prepared.

Unfortunately, the knowledge and ability to perform such feats are not acquired by techs who feel their job is that of parts and box changers. It takes study, practice, testing, advanced diagnostics, knowledge of how systems really work, and how real efficiency is truly crafted is what’s necessary. This isn’t learned in trade schools or from manufacturers. This takes drive and outside-the-box thinking and learning.

The question is; are you inquisitive enough? Do you care enough? Are you willing to pay the price to be one who pursues such knowledge and exercises new skills on a daily basis?

This is what it takes to charge prices like Tesla and thrill your customers as he did Henry Ford.

Perhaps Some Services Are Only a Commodity

In preparation for a presentation coming up in a few weeks, we conducted a brief informal survey among service technicians who had not been trained in a utility program we manage.

The results showed that during about 75% of their repair visits, the typical technician merely replaced something: a fuse, a thermocouple, a control board. Or that technician replaced a furnace when its heat exchanger cracked, or installed a new condensing unit when a compressor failed.

Unfortunately, we discovered the prevailing philosophy in many companies was to simply keep replacing parts until the equipment starts to “work” again. We were left to wonder what these guys and gals are doing that could be worth more than the 3% net profit our industry suffers from? The answer: not much.

Among those we surveyed was a belief that delivering efficiency is being satisfied by the equipment manufacturers. The survey also revealed the average technician only has an estimated repertoire of 30 basic repairs.

Not all of us can be a Tesla. But each of us has the ability to shine as he did when circumstances are right. It’s said that “Luck favors the prepared.” Perchance better preparation will provide each of us with increased opportunity.

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC based training company and membership organization. If you're an HVAC contractor or technician interested in a HVAC System Diagnostic Procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles and downloads.

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.