EDITOR'S NOTE: This article was updated with new graphics and a video.

Many of the responses to my last article "How to Balance a Residential HVAC System," asked about static pressure measurement, so let’s stick with the basics and take a look at how to measure residential static pressure in six simple steps.

Static Pressure Testing, Step By Step

It typically should take less than five minutes to measure a residential system’s static pressure. Here are sample instructions for a furnace and an external coil:

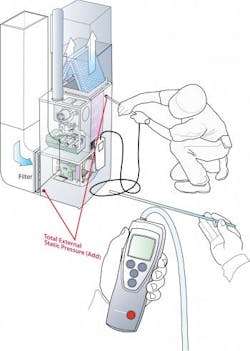

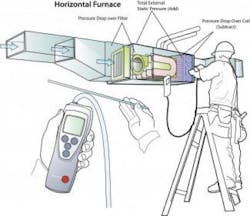

STEP 1: Locate the appropriate locations to drill the test ports on the supply side (+) between the furnace and the coil, and on the return side (-) between the filter and the furnace. Center the test ports for a neat appearance. Stay away from any coils, cap tubes, condensate pans, or circuit boards to avoid damage. Always look before you drill.

STEP 2: Drill test ports using a 3/8-in. drill bit with a metal piercing tip. A bullet-tip drill makes a clean round port. Make sure to use your drill bit sheath (described above) to help prevent you from drilling into the coil. If there’s a duct liner inside, be sure to penetrate it to assure a good reading.

STEP 3: Push one end of the tubing onto a static pressure tip. Place the other end of the hose on the HIGH (+) pressure port of the gauge. If required, make sure the gauge is level and zero it out by adjusting the screw on the face with a small screwdriver. Digital gauges each zero differently, so check the owner’s manual.

STEP 4: Read the supply or positive (+) static pressure by inserting the static pressure tip into the test port with the tip facing into the airflow. The magnet on the tip will hold it in place while the value is read and recorded. This measurement is the pressure the fan is “seeing” on the supply side of the system.

STEP 5: Read the return or negative (-) static pressure by moving the tube from the HIGH to the LOW-pressure port on the gauge. Insert the static pressure tip into the test port on the return side with the tip facing the airflow. Read and record the negative static pressure. Don’t forget to insert port plugs into the test ports when you’re done testing.

STEP 6: Calculate the system’s Total External Static Pressure by adding the two values. Since the negative and positive signs identify the type of pressure measured, you can ignore them when adding the two values together.

For example:

The supply static pressure reading is (+) .26 w.c.

The return static pressure reading is (-) .21” w.c.

The total system static pressure is .47” w.c.

.26” + .21” = .47” w.c

National Average Residential Static Pressures

Unfortunately, the example above is misleading. In reality, the average U.S. residential total external static pressure for a system rated at .50” is actually .82”.

If you convert static pressure to blood pressure, this would mean the average U.S. blood pressure would be 130 over 200. We checked with physicians and confirmed that a patient with blood pressure measuring 130 over 200 would not be permitted to leave the doctor’s office or hospital until a remedy to the problem was found and pressures returned to close to normal.

Static Pressure Diagnostics

Diagnosing with static pressure is straightforward. Compare rated total external static pressure to equipment rated maximum total external static pressure.

HVAC pressure diagnostics have similarities with blood pressure diagnostics. Good blood pressure is 120 over 80 by most standards. High blood pressure isn’t good and usually indicates excessive restrictions in your arteries.

Lower than normal blood pressure may be evidence of a weak heart or leakage in the arteries.

Total external static pressure that is higher than the rated total external static pressure may indicate excessive restrictions in the air distribution system.The same diagnostics are often true of low total external static pressure. Very low static pressure suggests a low fan speed or leakage in the duct system.

Further testing may include pressure drop measurements to determine the contribution of each component to total external static pressure of the system.

When you measure static pressures in the systems your company designs and installs, you’ll gain tremendous insight into system performance. Doesn’t it seem strange that the duct system is excluded from 98% of service agreements? It’s clear the pendulum has swung too far in the direction of equipment and away from comfort.

If static pressure is high, you have evidence of low airflow. Check for blockage in ducts, closed dampers, improper transitions, offsets, or kinked flex ducts. The problems can also be from the equipment and system accessories like “High Efficiency” cooling coils or restrictive filters.

Low static pressure can also mean trouble. Low pressure may indicate leaking ductwork or plenums, missing filters, low fan speed, or separated ductwork.

The Opportunity

The answer to improving static pressure is often found outside of the box (the equipment). Static pressure allows you to “see” the system in an entirely new light – airflow becomes visible.

The result of measuring static pressure is the ability to prescribe duct renovation work. You begin to see that the duct system is what controls comfort and efficiency. Only by getting the ducts operating properly can you assure the system as a whole is operating properly. Equipment is only a component of your system.

Everyone who sells high efficiency equipment thinks they are distinguishing themselves from their competition. That is simply not the case. High-efficiency equipment has been around for more than 30 years!

The new frontier is the duct system

When it comes to value, a properly installed, tested, and balanced duct system is worth far more than a new furnace. What sets you apart from your competition? Your ability to design, install, and balance a duct system sets you apart from your competition.

Static pressure measurement unlocks the door to the system as a whole. You can gain access to an amazing amount of duct repair and renovation work from the systems you service every day. The margins are extremely high and the skills required to perform duct renovation are minimal.

Rob “Doc” Falke serves the industry as president of National Comfort Institute, an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a free static pressure test procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles, and downloads.

VIDEO EXTRA: STATIC PRESSURE TROUBLESHOOTING BY FIRE & ICE

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.