Sizing a replacement belt after installing a new pulley can be tricky. Instead of buying five or six new belts, try applying the following formula and using these tips.

When you spin an adjustable pulley and increase its diameter to squeeze a little more air out of a belt-drive fan, there are times you’ll find the old belt no longer fits. The first fix is to loosen the bolts on the motor mount and slide the motor as close to the fan as possible to see if the belt will slip over the edge of the pulley. If that doesn’t work its time to surrender muscle to brainpower and calculate the size of a new belt.

It’s important to size and choose the right new belt for the job. Your choice is critical to the long-term performance of the system. Let’s look at not only how to resize a belt, but also what the steps are to be sure the job is done right the first time.

size fits the pulleys and make sure the bearings, shafts, and set screws are in good condition and secure.

While you’re at it, inspect the motor mount, the fan and housings to be certain they will remain in good working order after the new airflow is set so the equipment can operate long term. We’ve all serviced equipment, only to have it die a short time later. Nobody’s happy when that happens, so look past the new belt.

Record the old belt number written on the exposed surface of the belt. This is your best reference to find the belt’s original size, type, and length. If you don’t have the replacement belt on your truck, these numbers come in handy for the inventory crew to verify your measurements by cross referencing the belt number with the manufacturer’s catalog. A faded page in a manufacturer’s catalog is more accurate than field belt and pulley measurements any day.

Second Step: Do the MathSeveral measurements are necessary to complete the formula. Measure and record the distance between the motor shaft and the pulley shaft, and then measure the diameter of the motor pulley (also called the drive pulley or sheave) and the fan pulley (called the driven pulley).

Apply the following formula to determine a new replacement belt length:

Belt Length = 2C + 1.57 x (D1 + D2) + 1”

Where

C = The distance between the motor and fan shafts

D1 = The diameter of the small pulley

D2 = The diameter of the large pulley

The math is quite easy; it simply includes adding and multiplying. Here is a completed formula to walk you through the steps:

Example:

C = (12”) Distance between shafts

D1 = (3”) Diameter of the small pulley

D2 = (8”) Diameter of the large pulley

New Belt Length =

2C + [1.57 x (D1 + D2)] + 1”

2 x (12”) + [1.57 x (3”+ 8” )] + 1”

24” + [1.57 x 11”] + 1”

24” + 17.27” + 1” = 42.27”

So, select a new belt the next length above 43 inches.

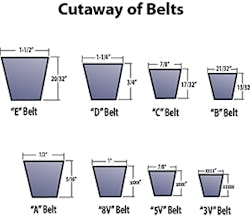

Next, determine the thickness of the belt. This is determined by measuring the cross section of the belt. Be careful, old belts may be badly worn sothe dimension may not be accurate. State the new belt size by stating its length and its cross section nomenclature.

The key to success when selecting replacement belts is having a huge inventory, or a great counter guy or gal at your distributor. They know the right questions to ask and can nearly finish your sentences once they get to know you or your company. Each is worth their weight in adjustable pulleys.

Tips for Adjusting Belt Tension

and Alignment

Amp Draw: When increasing pulley size, always check amp draw immediately after making the change. Remember, Amps increase at the cube of airflow, so a 10% increase in airflow may increase the power the motor draws by more than 30%. Pulley adjustments can be hazardous to the health of your motor. Do not leave a motor operating at more than full load amps.

Always measure fan RPM. Check the fan speed against the manufacturer’s fan data to be certain you don’t go over the fan curve. Airflow may decrease with an increase in fan speed under certain conditions.

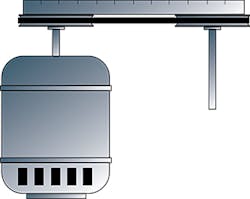

Adjusting the motor mount is accomplished by loosening the bolts that hold the motor onto the motor mount. Next, slide the motor closer to or farther away from the fan until the correct belt tightness is achieved, then tightening the bolts on the motor mount to hold the motor in place and keep the belt tight.

Pulley alignment: Sometimes you’ll need to loosen the set screws on the pulley and slide them along the shaft until the pulleys line up with each other. Alignment increases efficiency and prolongs the life of the belt and pulleys.

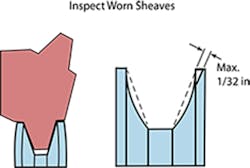

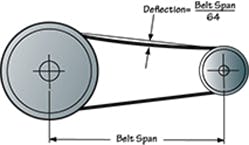

Belt tightness: How tight should the belt be adjusted? Too tight, and the power consumption mayThe rule I use for belt tightness is that belt deflection with moderate pressure applied should be 1/32nd of the distance between the shafts of the fan and the motor. For example if there is 16” between shafts, belt deflection should be 16” divided by 32 or ½”.

One last tip: With blower motors over 10 hp, it’s recommended that a good quality belt changeout include a second visit a day or two later to tighten the stretched belt by adjusting the motor mount. The belts do stretch and need to be tightened to perform their best.

Rob “Doc” Falke serves the industry as president of National Comfort Institute -- an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a free belt replacement sizing procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles, and downloads.