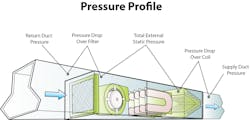

All air moving equipment comes with specifications to be met when it is installed. Installations not meeting these specifications deteriorate system efficiency. One of these specifications is total external static pressure. Let’s take a look at energy penalties imposed when a system’s static pressure exceeds published specifications in the field. System efficiency losses exceeding 25% are common.

Technicians who add static pressure measurements to their service and diagnostic routines, soon understand the scale of the excessive static pressure epidemic they face.

Many technicians report the typical total external static pressure (TESP) exceeds rated equipment pressures from 150% to 180% or more. Less than one in 13 blower motors operate within published static pressure specifications.

To put this into perspective, a residential service technician may only find one system every two to three days with operating static pressures below the nameplate rating. Twelve of 13 systems may need static pressure testing, diagnostics, and repairs.

Bottom line, these energy penalties are hidden from most “technicians and are rarely considered by most contractors and energy efficiency programs.

Energy Penalty

To quantify the precise energy penalty each individual static pressure flaw causes is difficult and usually not worth the time or the cost to quantify it. Especially because each system is unique and one static pressure repair does affect the other pressures in the system.

However, you can “see” the penalty by scoring installed system performance before and after repairs are made. You CAN take readings to confirm repairs are improving system efficiency for each static pressure problem you solve.

Few will argue that diagnostics and repairs which bring a system into compliance with its published specifications, results in increased efficiency. This is especially true for your customers, who see and feel immediate results, solving their longstanding comfort and energy complaints.

Here are the top six typical causes of excessive static pressures. We’ll also look at why each problem increases system static pressures, and how the problem can be diagnosed and repaired.

Overly Restrictive Air Filters

Problem – Air filters are inserted directly into the air stream. Each air filter has a published pressure drop, at a specific airflow, indicating its restriction to airflow. Typically, the higher the filter efficiency, the higher the airflow resistance. Also, the dirtier the filter, the more obstructive it becomes.

Diagnostics - Air filter static pressure is measured by installing test ports on both sides of the filter and measuring pressure before and after it. Subtract the two pressures, to find filter pressure drop.

NCI Static Pressure Budgets show no more than 20% of fan rated pressure should typically be consumed by the air filter. For example, if the fan is rated at a maximum of .50” w.c., multiply that by .20 (20%) to find the maximum filter pressure drop. In other words: .50” x .20 = .10” maximum recommended filter pressure drop.

Repair - If the filter pressure exceeds the maximum filter pressure drop, you should upgrade the filter. Repairs include installing a less efficient or less restrictive filter. Or, you can increase filter surface area to reduce airflow restriction.

Cooling Coils

Problem – Indoor coils are also installed directly into the airstream. Most higher efficiency coils are extremely restrictive to airflow. Unfortunately, some designers give little consideration to coil pressure drop when specifying fan airflow and static pressure capacity.

This means fans cannot deliver required airflow to allow the system to function efficiently. I’d recommend you spend an hour comparing coil pressure drops to the fan-rated static pressure of the high efficiency equipment you install. Odds are your equipment selection habits will change immediately.

Diagnostics – Measure static pressure entering and exiting the coil. Subtract the two measurements to find the coil’s resistance to airflow. Ideally coil pressure drop should not exceed fan-rated pressure by more than 40%. If the fan is rated at .50”, the coil pressure drop should not exceed .20” (.50” x .40 = .20”). Good luck matching up an efficient coil to a .50” fan with today’s equipment.

Repair – For an existing system, if the coil exceeds 40% of fan-rated pressure, it may have become dirty and must be cleaned. If the coil is new, it should be replaced with a less restrictive coil, which will most likely be less efficient. Or you can install a fan with increased capacity. These are both very expensive repairs making them difficult system upgrades to sell.

Another option is to rebuild the system with a very low pressure drop filter and an oversized duct system to compensate for the high-pressure drop coil. It takes careful field testing and system redesign to be successful. Hopefully your company will make a habit of comparing coil pressure drop to fan capacity before designing systems and purchasing equipment.

Duct Design and Installation

Problem - Undersized ducting is a major problem across the country. The father-to-son, supervisor-to-technician idea that a 6” duct delivers 100 cfm just isn’t true. Add to that challenging installation conditions in tight spots or with long duct runs, and the system is in trouble. The only effective way to verify duct design is with field pressure and airflow measurement of the installed system.

Diagnostics – You can field-measure and evaluate the energy penalty caused by undersized and poorly installed ducts in a few minutes. Install static pressure test ports where the return air duct ends (often before the filter) and where the supply duct begins (often after the coil). Measure and record each pressure.

Remember, each side of the duct system should be no greater than 20% of rated fan static pressure. A .50” rated fan should have no more than .10” of pressure in the supply or return duct system. An .80” rated fan should have no more than 20% of fan rated pressure or .16” (.80” x .20 = .16”).

You can find duct restrictions by measuring pressure on both sides of a suspected restriction and subtracting the two pressures from each other. If the pressure drop exceeds more than .05”, a repair is usually needed to reduce resistance to airflow.

Repair – Undersized duct problems are remedied by upgrading duct, removing restrictions or by increasing duct capacity. You can increase duct capacity by adding additional ducts to a system. These repairs are included in what is an Air Upgrade to an HVAC system.

On the supply side, when a room is short on airflow, an additional duct can be cut in from the trunk or plenum. Return duct system capacity can be increased by adding larger ducts or a new return duct to an open room in the building.

Refrigerant and Combustion

Problem – The correct amount of airflow is required for refrigerant or combustion to function properly. Energy penalties caused by low heating and cooling heat transfer are well-documented.

Diagnostics – Measure and use the total external static pressure measurement with the fan speed to plot fan airflow using the manufacturer’s fan performance tables. Compare plotted airflow to required airflow and recommend needed repairs.

Remember, if you diagnose with system air temperatures only, the air volume over the equipment must be known before interpreting your temperature, refrigerant, or combustion readings. Both refrigeration and combustion temperatures change with airflow. The higher the airflow, the lower the air temperature drop or rise. The lower the airflow, the higher the temperature drop or rise.

Repair- Before effectively diagnosing refrigerant or combustion issues, make repairs described in the sections above to lower static pressure and increase airflow through the system. Only when airflow is verified to be within the manufacturer’s specifications, can effective diagnostics and repairs be made.

Blower Motor Watt Draw

Problem – As static pressure increases, constant-speed blower motors, under most conditions, suffer significant airflow decreases. The result: poor hear transfer and low system performance. Variable-speed fans maintain required airflow at higher operating static pressures to a point, but the blower motor watt consumption may increase from 200% to 350% higher than the watt draw when equipment efficiency was rated in the lab. This is a direct and easy way to measure this energy penalty.

Diagnostics – Find the blower motor watt draw used when the equipment efficiency was established in the equipment specifications. Then measure operating blower motor watts of the system operating at high static pressure. Compare the two watt draws. Verify the decrease in watt draw once you reduce system static pressure.

Repair – Use the diagnostics and repairs described above to reduce total external static pressure. This will reduce blower motor watt draw and increase system airflow and efficiency.

Increased Duct Leakage Near the Equipment

Problem – As much as 80% of duct leakage happens near the equipment where pressures are the highest in the system.

Diagnostics- Measure the static pressures in the duct system where air enters and exits the equipment. Document your readings. Repeat the pressure readings after repairs air made to reduce pressure. For each 10% total external static pressure is reduced, it’s reasonable to estimate leakage reduction near the equipment of up to 15%.

Repair – Completing the diagnostics and repairs above will decrease static pressure and air leakage near the equipment and throughout the system. Measure live duct leakage to document system improvement and provide evidence of energy savings.

Static pressure measurement allows you to detect and repair static pressure energy penalties., These static pressure energy penalties unknowingly offset energy efficiency benefits you promised your customers from their new replacement equipment.

Rob “Doc” Falke serves the industry as president of National Comfort Institute, Inc., an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a free test to measure total external static pressure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles, and downloads.

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.