Better contractors who build duct systems that exceed minimum code requirements find their customers will pay premium prices for the benefits they receive. Let’s take a look at five duct installation practices that significantly exceed code and increase the value and demand for better-performing duct systems.

Why Exceed Code?

Most contractors think duct systems are a loss-leader commodity, believing high-efficient equipment is where they make their profit. According to sales and installation practices that 90% of the industry uses, this is true.

However, a growing industry segment is making a very enlightened shift. They sell equipment as the loss-leader commodity and offer customized duct systems as their highest profit product.

Before long, they evolve and combine high-efficiency duct systems with high-efficiency equipment to deliver the best systems available.

Larger Ducts

In some areas of the country, code requires duct-sizing calculations that often fail to deliver a duct system that performs. This shortfall in performance identifies the gap between design and the installed system.

While engineering documentation satisfies code, you can surpass the minimum standards by increasing your duct sizes to build superior systems that deliver higher efficiency and increased comfort.

While many consumers want bigger equipment, the actual solution to their problem is often a larger duct system. All consumers want bigger and better, so offer the solution where it will do the most good … upsize the duct system.

Equipment alone is a commodity, sold by dollars per ton. A custom well-performing duct system is rare and not a commodity. Sell it for what it’s worth.

Duct Insulation

Code requires typical attic insulation to be R-38. Above the insulation in the hottest part of the attic, code requires using typical duct insulation of only R-8. Why is code duct insulation 75% less than required minimum attic insulation where both are subject to extreme temperatures?

Does this make any sense? Once you make your customers aware of this discrepancy, they become more willing to pay for you to add better duct insulation.

You can go two or three times beyond minimum code requirements by blanketing duct systems with 4 feet wide rolls of R-19 unfaced insulation. The cost to you is a small fraction of the benefit and savings to your customer.

Remember those customer complaints on extreme temperature days about how their system works great in the morning, but then produces minimal cooling in the afternoon?

This problem usually cannot be fixed at the equipment. The real problem is heat from the 130ºF attic penetrating the poorly insulated duct system. This defect may completely offset the cooling produced by properly operating equipment.

Remember those customer complaints on extreme temperature days about how their system works great in the morning, but then produces minimal cooling in the afternoon? This problem usually cannot be fixed at the equipment.

How often have you added several pounds of refrigerant that failed to solve this problem? Next time offer your customer a beyond-code solution; offer the new R-12 insulated duct as an upgrade or install an R-19 duct blanket around existing ducts. Be sure to price the service for all that it’s worth for you and your customer.

Inadequate Flex Duct Suspension

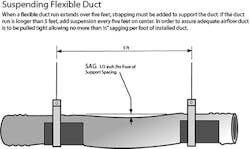

In many areas of the country, code only requires one inch of metal or “lawn-chair” strapping to suspend flexible ducts every five feet.

While this may work well until the inspector is gone, this type of support soon works its way into the flex duct, compressing duct insulation and the interior liner reducing airflow through the duct.

Exceed minimum code requirements by installing flex duct suspension every three to four feet on center rather than every five feet.

Another solution is to offer customers duct saddles attached to strapping that spread the weight over 12 inches of the duct. This greatly increases duct system life and performance and is an easy-to-understand benefit consumers are inclined to pay for. Certainly, this is not a commodity priced service.

Exceed minimum code requirements by installing flex duct suspension every three to four feet on center rather than every five feet.

If nothing else, slip a square foot of roofing felt or rigid material between the strapping and the flex duct to achieve similar results and deliver superior duct systems.

Replace Deteriorating Duct

Code officials often inspect equipment changeouts without any concern for the condition of the ducts attached to that equipment. The general code assumption is the duct system is good for the life of the building.

On a recent conference call, I polled a half dozen HVAC contractors from the Southern United States. The question: “How many years until you can stick your finder through flex duct installed in attics in your area?” Answers ranged from 7 to 20 years, with the average being just under 15 years.

Suggested action? Persuade your customer to stick their finger through a dilapidated duct. Welcome to the zone of no competition sales and service. How’s that for advanced air diagnostic testing?

It becomes obvious that replacing aging flex duct is a premium duct system upgrade you can offer.

Verify the Results of Your Design and Installation

Talk’s cheap. Add an iron-clad promise to your duct upgrades. Prove the design and installation of your system far exceed minimum code requirements by testing the system upon completion.

Air testing and balancing have been the specified HVAC system installation audit for five decades.

Testing and balancing include measuring system airflows, air pressures, as well as equipment and duct temperatures. By plugging these measurements into a few key mathematical formulas, you can document and prove you delivered the high-quality duct system your customer purchased from you.

Remember: building codes are minimum requirements that reward contractors with minimum profits. On your next job, focus on improving duct system performance with one or all of these beyond-code duct improvements.

Rob “Doc” Falke serves the industry as president of National Comfort Institute, Inc., an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a free residential Air Balancing Report and Procedure, contact Doc at ncilink.com/ContactMe or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, articles, and downloads.