I recently talked with my friend Ty Branaman, a fellow industry educator, who mentioned a disturbing trend he is seeing. Technicians and salespeople check Total External Static Pressure (TESP) and use it as the only measurement to determine whether a duct system and airflow are acceptable.

Those who follow this approach measure TESP and then only compare it against the manufacturer’s rated TESP on the air-handling equipment data plate. If their measurement is less than the manufacturer’s specifications, they stop and assume all is well. However, they condemn the duct system if their measurement exceeds the manufacturer’s rated TESP.

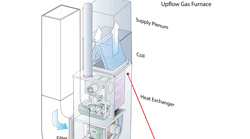

TESP looks at the total resistance the air handling equipment’s fan must push and pull air against.

While Ty and I are both grateful our industry is finally looking at the airside, this practice tarnishes a foundational airside measurement. It attempts to turn TESP into a silver bullet. In folklore and legend, a silver bullet is the projectile of choice to take down monsters. The term also describes a simple solution to a much more complicated problem.

Defining Total External Static Pressure

Total External Static Pressure (TESP) is the most common static pressure measurement. It is the one many in our industry refer to when discussing static pressure generically.

TESP looks at the total resistance the air handling equipment’s fan must push and pull air against. For example, let’s say you measure pressure entering and exiting the air handling equipment. Return side pressure (entering the equipment) is .45 in. w.c. (inches of water column) and supply side pressure (exiting the equipment) is .05 in. w.c. When you add these two readings together, they equal .50 in. w.c. (.45 + .05 = .50).

Many measure TESP with two hoses connected to a manometer that calculates the display reading. This is where the TESP silver bullet problems begin.

At National Comfort Institute (NCI), we recommend looking at the individual pressures that make up the total. Doing this helps you see which side of the fan has the highest resistance to airflow. Unless you look at those individual readings, you can easily be tricked into thinking a problem exists that does not or completely overlook one that does. Your diagnosis is based on limited information.

At National Comfort Institute (NCI), we recommend looking at the individual pressures that make up the total. Doing this helps you see which side of the fan has the highest resistance to airflow.

In the example above, all the pressure is on the return side. If you only look at total external static pressure, you’ll miss a problem like this every time. Just as refrigerant gauge pressures don’t tell the entire story of a refrigeration system, TESP doesn’t tell the whole story of the HVAC system. Missing information causes you to miss the target.

Missing the Target

When using a bullet, you need a good firearm, great aim, and an obvious target. One of the basic rules in hunter safety education is to know what’s behind your target and what obstacles you may encounter. Some of the most common obstacles that caused me to miss the target with TESP were:

- Test ports in the wrong locations

- Testing with a dirty blower wheel, air handler coil, or secondary heat exchanger

- Assuming fan airflow

- Ignoring the blower speed and fan capacity

- Operating the blower at a lower speed using the “fan-on” thermostat setting

- Leaky ducts

- Testing too close to turns, corners, or dead spots

- The static pressure tip was behind the duct insulation

- Using poor quality manometers.

If you want to shortcut the learning curve, study my mistakes and avoid those assumptions that got me into trouble. Once I got the proper training, I saw how important it was to look at the condition of the air handling equipment and individual pressures on both sides of the fan. I soon realized measuring TESP alone wasn’t enough and was leading me down the wrong path. If you add up the mistakes I made above, you can see how quickly problems compound.

Context is Everything

For decades, NCI has compared TESP to the blood pressure of an HVAC system. It helps indicate overall HVAC system health and is vitally important. However, no physician would recommend open-heart surgery based on a single blood pressure test. They need additional information and measurements to pinpoint the problems. Blood pressure readings only provide a clue.

TESP only tells part of the story without fan airflow. I have been the victim of finding excellent TESP measurements but unacceptable airflow. Conversely, I’ve also seen excessive TESP with too much airflow. In both scenarios, I made assumptions and omitted essential data to diagnose accurately. Some of the most critical data to consider are:

- Operating fan speed

- Blower wheel cleanliness

- How the manufacturer rated the air-handling equipment

- Fan tables to plot fan airflow (manufacturer tables work best, but NCI generic tables will work in a pinch).

I also needed additional static pressure measurements to identify the most significant areas of resistance to airflow. Essential pressure measurements are:

- Indoor coil pressure drop (ΔP)

- Air filter pressure drop (ΔP)

- Return duct pressure

- Supply duct pressure.

Each of these pressure measurements, along with fan airflow, work together to help you identify potential airside issues.

Thankfully, there are test instruments that directly measure airflow, like the Digital TrueFlow Grid from The Energy Conservatory (TEC). It combines essential static pressure measurements and measured fan airflow into a package that makes sense with an easy-to-follow workflow.

If you’re measuring Total External Static Pressure, that’s a great start. Just remember, it’s easy to fall into the trap of looking at TESP as a silver bullet. Instead, consider it a single pellet in a silver shotgun shell. Packing a punch requires a lot of other pellets in the same container. Once you combine it with other missing pellets from your testing arsenal, you can hit a wide variety of duct systems and airflow targets that were previously hidden.

David Richardson serves the HVAC industry as Director of Training for the National Comfort Institute, Inc. (NCI). NCI specializes in training focusing on improving, measuring, and verifying HVAC and Building Performance.

If you’re an HVAC contractor or technician interested in learning about how to apply static pressure measurements the right way, contact David at ncilink.com/ContactMe. NCI’s website, www.nationalcomfortinstitute.com, is full of free information to help you improve your professionalism and strengthen your company.