How HVAC Contractors Can Protect Structures from Acidic Condensate

Energy efficiency and sustainability are key drivers in the building design and construction industries. Look closely at the residential sector and it’s clear that these trending buzzwords have a major impact on almost every aspect of home building, design and renovation—down to the type of heating appliances used in the home.

The U.S. government is a key driver of this energy efficiency and sustainability movement. In late 2023, the Department of Energy (DOE) finalized a residential gas furnace efficiency standard. This landmark rule will go into effect in late 2028 and will require non-weatherized gas furnaces and those used in mobile homes to achieve an annual fuel utilization efficiency of at least 95%.

While this energy efficiency standard will ultimately support the U.S. government’s sustainability targets, the increased adoption of high-efficiency, gas-fired heating appliances presents both challenges and opportunities for the industry. Similarly, it poses the question: are you prepared to meet the latest standard?

Meeting the DOE’s new energy efficiency standard with condensing appliances

To achieve compliance with the new DOE mandate, all gas furnaces are expected to utilize condensing technology, which incorporates a secondary heat exchanger to recapture the combustion gases and extract additional heat. In fact, the DOE explicitly states that the new energy-efficiency standard is “readily achievable by modern condensing furnaces.”

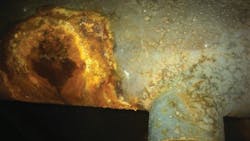

While a game-changing innovation, the condensing technology used in high-efficiency gas furnaces creates an often overlooked or misunderstood byproduct: acidic condensate. Unlike air conditioning condensate, this residue is acidic (e.g. pH of 2.9-4.0) and can corrode plumbing, concrete foundations, floor drains and wastewater systems, and pollute groundwater and the environment.

Untreated acidic condensate can eat through many types of building materials, including concrete foundations and cast-iron pipes (common in older homes)

Condensate neutralizers are the purpose-built solution to the acidic condensate issue

However, there is a simple solution to this emerging issue: install condensate neutralizers on every condensing furnace. Essentially, condensate neutralizers are purpose-built filtration devices that raise the pH level of the acidic condensate (reducing its acidity) to a safe level before it’s discharged into the plumbing and wastewater systems. This in turn helps prevent potential damage to the appliance or property. As such, condensate neutralizers are a must-have accessory on every condensing furnace installation to achieve code compliance and ensure that high-efficiency appliances fulfill their environmental promise.

Capitalizing on the condensate neutralizer market opportunity with preventative maintenance

Like any modern technology, condensing furnaces require routine maintenance to ensure efficient operation. Our industry has a renewed focus on preventive maintenance programs and service contracts to deliver recurring revenue and help mitigate the costs to owners of these modern, high-efficiency furnaces. To that end, contractors can capitalize on the market opportunity by incorporating the installation and/or servicing of condensate neutralizers into their annual maintenance programs for condensing furnaces.

Looking ahead

As more homeowners across the country make the switch to condensing furnaces in the coming years due to the DOE’s new standard, contractors and similar industry professionals will be expected to be familiar with all aspects of these relatively new systems—including how to safely and effectively treat acidic condensate. The exciting part is that you can prepare to set yourself, your business, and your customers up for success to capitalize on this market opportunity.

Kyle Emmons is President of JJM Alkaline Technologies, a leading designer and manufacturer of acidic condensate neutralizer products for the heating and plumbing industries.

Kyle leads the overall organization with a particular focus on growth, including sales, marketing, and new product development. He has over 15 years of middle market private equity, mergers and acquisitions, and operating experience. A native Texan, Kyle received a Bachelor of Business Administration degree in Finance from Texas Christian University and earned his Master of Business Administration from the Kellogg School of Management at Northwestern University. https://jjmalkalinetech.com/