Fabric HVAC Diffuser Retrofit a 5-Star Solution for 'Mrs. Doubtfire' Restaurant

Facing seemingly insolvable performance challenges from its kitchen ventilation system, Bridges Restaurant & Bar, Danville, CA, was ready to outlay upwards of $20,000 for a new rooftop make-up air system.

Instead of exiting through the dual exhaust cooking hood, smoke and food odors wafted into portions of the 3,300-sq.ft. dining area, raising complaints from patrons seated near the kitchen.

The 24-year-old, independently-owned Bridges is popularly known in the San Francisco area for its casual-elegant dining, and also as the location for actor Robin Williams' comedic multiple costume changes in the 1993 Hollywood movie, "Mrs. Doubtfire." Because of its upscale image and popularity, the vexing dining area cooking odors were bad for business and affected the overall guest experience, according to Kevin Gin, executive chef and a member of the restaurant's investor consortium.

Additionally, drafts from the existing make-up air HVAC system were drawing smoke and grease, that should have been contained within the cooking exhaust hood, and depositing them onto the diffuser, walls ceilings and other kitchen surfaces requiring more than $1,000 annually in maintenance labor and cleaning compounds.

Besides odor infiltration and maintenance costs, the drafts from the air conditioning supply over the food prep area was prematurely cooling prepared hot entrées, while employees in other kitchen areas were uncomfortably hot.

Finding a Low Cost Solution

A large HVAC retrofit outlay seemed imminent until an arranged meeting between Gin and an HVAC ventilation product manger attending a Bridges-held 25th anniversary dinner for the nearby Food Service Technology Center (FSTC), a San Ramon, CA-based commercial foodservice equipment performance test lab funded by Pacific Gas & Electric. Nick Paschke, product manager at textile HVAC ductwork manufacturer, DuctSox Corp., Peosta, IA, recommended a custom textile air dispersion system designed specifically for kitchens. The ceiling-mounted device disperses airflow uniformly, parallel and in front of the kitchen exhaust hood. The fabric diffuser is an easy-to-install replacement for metal air distribution diffusers that commonly cause kitchen exhaust hood overflow.

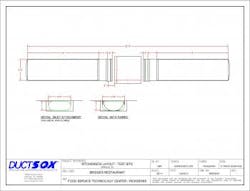

Located over the food prep line to distribute air throughout

the 1,000-sq.ft. kitchen, the diffusers were replaced

with two 8-ft.long, 28-in.-diameter D-shaped

KitchenSox fabric diffusers.

Instead of a 5,000-cfm make-up air equipment replacement, only the kitchen's lone conventional 3 x 3-ft. supply box and four metal diffusers were switched out. Located over the food prep line to distribute air throughout the 1,000-square-foot kitchen, the diffusers were replaced with two 8-ft.long, 28-in.-diameter D-shaped KitchenSox fabric diffusers. Instead of the metal diffuser's estimated 500-fpm airflow that caused turbulence and disruption of the cooking hood's capture, the air is gently and evenly dispersed through the fabric into the entire kitchen area at a significantly slower 85-fpm rate. Without the previous high velocity airflow and subsequent turbulence, the dual exhaust cooking hood now efficiently performs up to its design standards and captures smoke, grease particulates and cooking odors without overflow.

CulinAire Systems, El Dorado Hills, CA — a foodservice ventilation contractor specializing in demand ventilation controls and engineered kitchen ventilation equipment — fabricated the sheet metal plenum and metal/fabric adaptors that supply the 16 linear feet of fabric duct. The fabric duct system and metal accessories were installed by CulinAire overnight without disruption to the kitchen operation.

Without the drafts, the excessive airborne smoke, grease deposits and dirt that the return air system had once drawn onto diffusers, kitchen walls, ceilings and cabinets no longer occurs, which has expedited daily cleaning and sanitation routines.

Gin also plans annual cleaning since the fabric diffuser can be disassembled by kitchen staffers in just minutes and commercially laundered, a process that would require days to complete by an outside contractor with a metal system.

Green Mission Accomplished

By improving the air distribution and eliminating the hood's hot air overflow into the kitchen, a considerable energy savings supplements Bridges' green mission, which is strategically marketed among its clientele. Gin said it's difficult to pinpoint energy savings of the new system because FSTC continually uses Bridges as a beta test site for new technology. However, Gin did estimate recent Bridges' conservation efforts are saving the restaurant more than 20% in energy costs with quick investment paybacks.

For example, FSTC oversees results of Bridges' variable speed Intelli-Hood control, which is manufactured by Melink Corp., Milford, OH. The Intelli-Hood control won an "AHR Innovation Award" in the ventilation category at the 2012 AHR Expo in Chicago.

'Green' Products Used Included:

- Cyclone Xi 96% efficient hot water heater by A.O. Smith, Ashland City, TN

- variable temperature control for more efficiently running walk-in cooler operation by E-Control Systems, Sherman Oaks, CA

- high temperature/reduced water kitchen and bar dishwashers by Hobart Corp., Troy, OH

- lighting retrofit from standard bulbs to compact fluorescent

- the highest efficiency equipment available today in fryers, convection ovens and ice machines by Vulcan-Hart Co., Baltimore, MD; the Garland Group, Freeland, PA; and Manitowoc Ice Inc., Manitowoc, WI.

Bridges' challenges with HVAC ventilation was solved completely with fabric diffusers that cost less than 10% of the approximate $20,000 for a new make-up air system. Furthermore, the energy savings and reduced maintenance costs offer a payback of less than one year on the air diffusion system. "This is really a common problem (inadequate cooking hood drafting) I think many restaurants suffer from and don't realize there's a simple, inexpensive solution," Gin says. "We once thought replacing the HVAC system would improve our kitchen ventilation challenges, but we now realize it probably wouldn't have remedied what was actually a ventilation problem that fabric ductwork solved."

High Velocity HVAC Ventilation Often Disrupts Cooking Hood Exhaust

The kitchen ventilation challenges Bridges Restaurant & Bar, Danville, CA, had suffered for years were no surprise to engineers at the Food Service Technology Center (FSTC), San Ramon, CA, a commercial foodservice equipment performance test lab.

Prompted by many restaurants experiencing similar kitchen ventilation problems, the FSTC lab tested different solutions and prepared a report for the Customer Energy Efficiency Programs division of Pacific Gas & Electric Co."This (poor exhaust tendencies by cooking hoods) is a common problem in the foodservice industry ," according to Rich Swierczyna, senior engineer/commercial kitchen ventilation lab manager, FSTC. "The fabric diffuser slows the airflow down and allows the kitchen hood to exhaust properly."

Swierczyna says the common four-way metal diffuser typically produces velocities as high as 700 ft./min. (fpm) versus the 50 to 250-fpm of fabric diffusers, which slow the air down because it flows through the fabric's factory-engineered porosity.

For consultants designing new kitchens, four-way diffusers ideally should not be specified. Airflow from a one-way diffuser directed away from the hood or transfer air from an adjacent zone is a better design. However, fabric