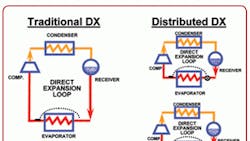

Most supermarket refrigeration systems follow the traditional approach of using centralized parallel racks connected to circuited pipe systems that circulate refrigerant throughout the entire store. These types of systems have been in use for years and have served customers well. However, other approaches are available for customers looking to satisfy specific goals beyond the capabilities of traditional systems. One such approach is the use of distributed systems.

A Different Approach

Traditional centralized parallel rack systems typically have two or more parallel racks in a single location to handle all of the refrigeration requirements for an entire store.

Within the two major groupings of loads in a typical store, there are almost always narrower ranges of temperature requirements beyond those of just medium-temperature and low-temperature. Medium-temperature applications, for instance, usually differ among diary (22F), meat (21F), seafood (20F), and produce (28F). Low-temperature applications also usually include different temperature requirements for ice-cream (-19F), frozen foods (0-5F), and walk-in freezers (-25F). Although the difference between loads within a group may seem relatively minor, the energy needed to meet a temperature requirement of just one degree (the difference between diary and meat, for instance) does add up. In order for a traditional centralized system to perform adequately, it must run the compressors for a given suction group enough to satisfy the lowest temperature requirement. In the example of the medium-temperature group above, that temperature is 20F, even though the other requirements in the group range upward to 28F. The result of this type of arrangement can be one of unneeded compressor capacity and wasted energy consumption. Improvements to traditional rack systems have addressed this problem by dividing the compressors on a rack into different sub-groups in order to better match the various temperature requirements of the circuits they're connected to, but this adds to the complexity of the store's piping.Distributed systems divide the loads into matched groups, with the compressors systems physically located closer to the loads they are cooling.

Distributed Systems Simplify Field Piping

Instead of a single system that sends refrigerant through the entire store to all the loads in either of two suction groups, the distributed approach divides the loads into a number of smaller systems and places the systems closer to the loads. This simplifies the field piping and reduces energy losses in the system by reducing the length of the piping runs. A typical distributed system store may have five or more units, each one of which is matched to a narrower set of loads. The units can be placed along the rear exterior of the store, or more often set on the roof, directly over the loads to which they are matched. Distributed system units are generally smaller than centralized rack systems (often including built-in condensers on exterior-placed units), therefore some versions of the units can be situated in back rooms or on top of walk-ins or coolers (requiring connection to separate condensers). Distributed systems can operate more efficiently and eliminate the need for an in-store mechanical room or a complete exterior machine house.

Advantages Include Reduced Piping

In a typical distributed system, anywhere from five to eight units — depending on the size of the store — are mounted on the roof. Although by virtue of their design, the units can be located practically anywhere, the greatest benefit usually comes from mounting them directly above the loads to which they are connected. Among the specific advantages of this kind of approach are: less piping (shorter runs and potentially smaller line sizes); less refrigerant; less potential loss from any one given leak; smaller compressors.

Traditional centralized rack systems may have pipe runs of more than 300 ft. from the machine room — usually at the back of the store — to service or produce cases at or near the front of the store. Multiply that amount of pipe a number of times over for different suction and discharge lines in each suction group of a circuited pipe system and you're talking a lot of pipe. By locating distributed units on the roof directly over the loads, the run length is greatly reduced; some as short as the height of the roof to the floor, approximately 30 ft. in most new stores. Besides significantly cutting down on the amount of piping in the store, these shorter runs reduce the amount of refrigerant contained in the piping (and the entire system), and reduce the potential quantity that could be lost from any single leak. Less overall refrigerant in the system means lower first costs for the customer. With the refrigerant that's in the store divided among multiple distributed systems, any leaks that occur result in no more refrigerant loss than the amount that is contained in one system. With traditional systems, a leak could result in a loss of the entire refrigerant charge.

Shorter line runs decrease the amount of area through which unwanted heat gain from the store can occur, and reduce pressure losses in the refrigerant flowing through the pipes. The result is improved energy performance.

Page 2 of 2

Sustainability Benefit

One of the biggest concerns in the industry today is that of sustainability. As the regulatory structure and consumer attitudes change, customers have moved increasingly toward so-called “greener” operations that save energy and reduce their carbon footprint. With the advent of various global initiatives and conventions such as the Kyoto Protocol and other agreements, the supermarket industry has become an easy target due to its high leak rate (an average of about 25% across the industry) and high global warming numbers for its refrigerants. This has resulted in, among other moves, the phase out of some refrigerants (R-22, for instance) and the higher cost and taxing of others — as of Fall 2008, for instance, the tax on R-404A in Denmark was over $32 per pound. In the U.S., regulatory compliance is expected to only get stricter. Customers are going to have to find alternatives to traditional approaches and distributed systems offer one of the most effective paths to greater sustainability.

Distributed systems use smaller compressors. Because suction groups are more closely matched, very little excess capacity is required to be designed into the system. Smaller, more energy efficient compressors can be used to provide only the capacity needed for each closely matched suction group.

While there are advantages in sustainability with distributed systems over traditional systems, the greatest reductions in carbon footprint and energy use with distributed systems come when they are combined with secondary refrigeration (see “Traditional Versus Secondary Supermarket Refrigeration,” Contracting Business, December, 2008, p. 50; or contractingbusiness.com/refrigeration/content/refrigeration_primary_secondary/). Distributed systems that employ both medium-temperature glycol cooling and low-temperature CO2 cooling enable customers to achieve some of the lowest refrigerant charge values possible for whole stores.

Installation Requires Separate Controllers

Each unit typically has its own controller and its own wiring to and from the cases to which it is connected. Structural requirements also include adequate support for each unit. Whereas a traditional system contained in a roof-mounted machine house requires support for just the single house and attached condensers, each unit of a distributed system must have its own. This requirement can add up to more steel.

Those concerns not withstanding, customer experience suggests that another benefit of more evenly matched loads is potential energy savings. Three to five percent reductions in energy use have been observed by some customers. Combined with lower refrigerant charges and leaks, these energy savings contribute to reduced carbon footprints and greater sustainability. The consumer attitudes noted above lead shoppers to stores that can make these claims. In the case of distributed systems, profitability and sustainability go hand and hand.

Bill Katz is a technical writer and course developer for the Hill PHOENIX Learning Center. He has written and developed training for the refrigeration and information technology industries. He can be reached at [email protected].