Flushing Techniques For R-22 to R-410A Conversions

Many contractors are experiencing compressor burnout problems with R-410A HVACR systems soon after they’re converted from R-22 refrigerant. A conversion should always include condenser, evaporator, and line-set change-outs, but the problem lies in the fact that linesets can’t always be changed out. It’s more economical for the equipment owner to retain linesets that run through walls or under concrete flooring. However those retained linesets must be flushed out properly before they’re used with the new R-410a equipment.

On-site flushing methods and/or materials appear to be the main culprit in post retrofit breakdowns because of the difficulty getting all mineral oil, acid and moisture traces out of the old system’s linesets. Combine the ongoing moisture battle that’s commonly appearing in POE oil systems along with these damaging residuals, and the result is sludge that leads to compressor seizing or inorganic mineral acids, that lead to a burnout.

We’ve performed several in-house tests proving that even miniscule amounts of residual impurities can manifest into mineral acid burnouts. Service technicians are scratching their heads wondering how a newly converted HFC/POE can burn out in just several months of operation. If the old linesets were retained, residual impurities are the main suspect.

Flushing Old Linesets is Key

Lines must be flushed properly. A triple evacuation will never remove mineral oil or the acid trapped inside the oil, because it only pulls out contaminants capable of evaporating. Additionally, evacuations won’t boil out particulates or acid and moisture that lie within the residual mineral oil. Remaining lineset particulates, acid, moisture, and mineral oil can combine into a sludge that’s similar to molasses. It won’t boil off, even if the system is under a vacuum for days or weeks.To ensure complete removal of the flushing compound, it too, must vaporize. Therefore, any un-pressurized liquid flushing solution from a jug is totally unacceptable, since it’s just trading the oil and other non-evaporating fluids in the system with another liquid impurity that also won’t evaporate. Given the complex chemistry interactions of HFC refrigerants and synthetic oils, this is a really bad idea. Instead, only flushing compounds that vaporize should be used, which means they are packaged in a pressurized disposable cylinder or pressurized aerosol can.

Basically, there are two major flushing solutions available at HVAC distributors. Only one solution is patented, biodegradable, and non-toxic, while the other is not. Results from a third-party laboratory test on both cleaning agents are available at www.qwik.com, so that service technicians can make their own decisions as to which is safer and a more effective cleaner.

Proper Lineset Flushing

Whichever cleaning agent is used, proper job preparation requires: 1) a method of getting the flushing agent into the lines; 2) create resistance with a restriction at the end of the line so the flushing agent flows slower and remains in contact longer with contaminants; 3) a receptacle such as a bucket at the other end of the lineset; 4) an access valve that fits the flushing agent container.Before using a flushing agent, nitrogen purging is recommended to blow out any loose particulates. The less particulates in the lines increases the dissolving power of the flushing agents on the remaining contaminants. Incidentally, this also blows out as much residual oil as possible.

Getting the flushing agent into the lineset requires some type of fitting. Some technicians braze on a-in. brass flared fitting that accepts the rubber hose from the flushing agent container. Brazing however, increases the preparation time. A more time-efficient method would be to wedge a conical rubber fitting into the open lineset, and hold it in position during flushing. Also, crimp the exterior end of the lineset to create resistance.

Technician Safety and Proper Disposal Methods

Always flush from inside the home or business to the outdoors. This will make clean-up easier, plus it will limit vapors. Regardless of using a safe, nontoxic flush or not, breathing any vapors is unnecessary. The used flushing agent will be collected in the bucket previously prepared at the outdoor openings of the lineset. Lawful disposal of the flushing agent is aFlushing agents are excellent for removing oil from linesets, but at the same time they should never be blown through a compressor because it will remove oil from the compressor and it will seize up. Likewise, never flush into a filter/drier because the large amount of particulates will reduce its filtering capacity. Thermostatic expansion valve (TXV) apertures and capillary tubes will clog as well. These aren’t major concerns because in a conversion or a system burnout/cleanup procedure, the compressor and filter/drier are typically cut out of the system.

Beside HFC to CHFC conversions, this flushing procedure is also recommended for burnout/cleanup work. The key is to use a biodegradable, non-toxic flushing agent that removes oil, water, and acid, and not just oil.

Checking For Acid

Another good practice for both burnouts and retrofits, is following up the final assembly of the system with an acid check, which is readily available for just a few dollars at any HVACR distributor. Moisture or acid can easily develop during the component assembly stage or refrigerant charging of a retrofit. The odds of acid are much higher in a burnout/ cleanup because acid is probably what burned out the system in the first place.

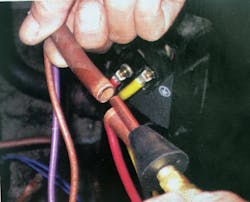

If acid is present, two types of acid removers can be used: 1) a neutralizing product that introduces an alkaline base to neutralize the acid (Figure, and 2) an acid flush that removes acid and moisture by absorbing it and flushing it to the filter/drier.

The latter method is recommended because it leaves no residue like the neutralizing process does. Residue is a contaminant that can eventually damage the system.

In most cases of retrofits, there are two kinds of flushes: 1) the system flush to dissolve or absorb an then literally blow out particulates, acid, moisture, and residual mineral oil in linesets that can’t be removed. This method of flushing is used when the system is disassembled and not operating; 2) the acid/moisture flush, to flush acid and moisture into the filter-drier of an operating system.

Robert Scaringe is president of Mainstream Engineering (www.mainstream-engr.com), and has been involved in the development of advanced vapor-compression heat pump systems for more than 47 years.

About the Author

Robert Scaringe

President

Robert Scaringe is president of Mainstream Engineering, Rockledge, Fla. He has been involved in the development of advanced vapor-compression heat pump systems for more than 33 years. He currently has more than 70 HVAC-related patents and more than 100 technical publications. To visit the company’s website, go to www.mainstream-engr.com. Mainstream’s HVAC service products division (www.qwik.com) includes EPA-608, EPA-609, IAQ, Preventative/Maintenance Tech, and Green online certification-training programs.