For the majority of commercial retailers, an “If it ain’t broke, don’t fix it” approach drives the selection of conventional refrigeration system architecture — one that centrally controls cases out on the floor, away from the rack house or refrigeration room in the back of the store. From start-up and installation to day-to-day operations and maintenance, these tried-and-true systems offer retailers a degree of predictability. But an increasingly competitive environment has forced them to seek alternatives to the status quo and look for innovative ways to reduce energy and operational costs in their refrigeration systems. As a result, many retailers are opening their eyes to the benefits of case control configurations that deliver optimized control at the individual case level.

Case control architecture enables control of all refrigeration case elements — such as lights, fans, anti-sweat heater, defrost and electronic expansion valves (EEV) — to deliver precise optimization across the entire refrigeration system. Compared to traditional, centrally controlled systems, case control is a flexible refrigeration method that’s capable of supporting a variety of configurations from simple to complex, including:

- Basic temperature control

- Superheat control via EEVs

- Electronic suction regulator (ESR) control

Because of its built-in flexibility, case control has earned a reputation among retailers for being challenging to configure and set up. Today, modern case control technology simplifies setup through adaptive algorithms that essentially eliminate configuration challenges at startup.

Modern case control refrigeration systems promise many benefits to commercial retailers, especially when combined with EEVs that enable low condensing operation and enhanced energy efficiencies. Reduced startup costs and maintenance activities, combined with improved operational visibility for troubleshooting and trend analysis, are some of the reasons case control warrants a closer look.

Electrical Installation Reduces First-time Costs

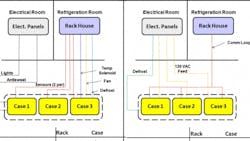

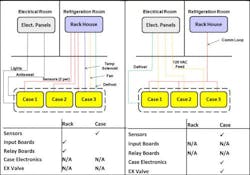

Retailers may associate case control systems with installation challenges and unwanted commissioning costs. In reality, installation is not only very simple, it even reduces installation costs. A closer look at the electrical architecture demonstrates where savings can be achieved (see Figure 1).

Centralized systems distribute control from the rack house or electrical room, and require excessive electrical runs to support the installation. Electronic control systems, such as input and relay boards, are located back in the rack house. Multiple low voltage electrical lines for temperature sensors (shown in the diagram as red lines) are wired from the rack house to each case on the floor; these are often referred to as “home runs.” Load controls, such as lights and anti-sweat heaters, are located in electrical panels.

In contrast, modern case control refrigeration systems simplify electrical configurations and provide all refrigeration controls at the individual case level. A daisy chain of temperature sensors is consolidated into a single, communications line, eliminating the need for multiple “home runs” to the rack house. Load switching occurs in the case itself (lights, fans, anti-sweats, etc.), reducing the number of electrical lines needed to run from the electrical panel to the refrigeration cases on the merchandising floor.

These significant electrical installation savings include:

- Reduction of electrical distribution feeder wiring

- Reduction and/or elimination of circuit panels and breakers

- Minimization of case field wiring

Since case electronics are mounted at the OEM (case controllers, sensors) during factory checkout, it eliminates much of the field work during installation … and leads to shorter commissioning time. But, with these changes to the electrical design and construction, retailers need to employ contractors who are familiar with this electrical architecture to realize the efficiencies of the case control architecture.

Note that this architecture requires an electronic case control system and EEV per each individual case. While this represents an increased cost for case electronics, the simplified electrical installation, startup costs and ongoing energy-reduction benefits more than compensate retailers for their investment.

Improved Startup and Commissioning

Historically, refrigeration startup is a time-consuming process — making sure everything is synchronized and configured properly can delay store openings and cause retailers to lose money. One advantage of using case control electronics with EEVs is their ability to automatically set superheat. This eliminates mechanical valve adjustments and the use of gauges to monitor conditions while trying to manually establish superheat settings.

Case control’s advanced electronics monitor temperature and pressure in real time, responding automatically to changing conditions and reducing the time it takes to set superheat. Technicians simply enter the set point, and the case control takes over to manage the rest of the process. Concerns about complex case control configurations — especially related to manually monitor the P and I constant settings — have all but been eliminated. Today’s case control systems are equipped with adaptive algorithms that make this process much easier, providing results that are as good as (or better than) the most expert technician.

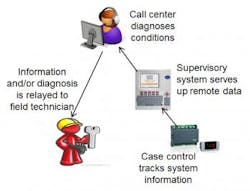

Eyes Into the System Help to Optimize Maintenance

The presence of temperature and pressure sensors in the case control provides visibility into complete refrigeration system data for diagnostics and troubleshooting. When combined with a supervisory control system, case control enables remote transmission of an abundance of information, giving operators eyes into the system to help optimize maintenance activities, including:

- Remote set point adjustment can eliminate the need for a service call

- Technicians can see real-time information about system conditions before they’re dispatched

- EEV’s automatic control of superheat makes the need for seasonal adjustments obsolete

- Allows the most expert technicians to have access to remote diagnostics and direct field activities at multiple sites from a central office, thereby combating a declining knowledge base in skilled technicians (see Figure 2)

-

Increased Potential for Ongoing Energy Savings

The precision with which case control and EEV systems deliver persistent system optimization provide ongoing energy-saving opportunities. In the evaporator, the EEV provides accurate control and eliminates parasitic losses found in mechanical thermal expansion (TX) valve systems. The EEV also ensures peak system efficiency at all times.One huge savings opportunity that can only be accomplished through case control with EEV systems is the ability to operate the refrigeration system at lower condensing pressures. Low condensing operation allows the head pressure to float with the ambient temperature and take advantage of lower temperatures that occur at night and in cooler seasons. Compared to conventional fixed head pressure operation, low condensing dramatically reduces mechanical stress on the system compressor and saves on energy costs:

- Lower energy consumption — 15%–20% energy efficiency ratio (EER) per 10 °F drop in head pressure

- Increased compressor capacity at lower condensing pressures

- Maintenance cost reduction due to less mechanical stress

Case control generates additional cost savings via precise control over the following functions:

- Localized, anti-sweat heater that response to case conditions

- Case lighting as determined by occupancy schedule

- Accurate defrost termination that shortens defrost cycles

It Pays to Make the Shift

At the end of the day, shifting from centralized control at the rack house to case level control provides many benefits to the commercial retailer. A simplified electrical architecture and factory-mounted wiring reduce installation costs. Electronic controls and advanced algorithms shorten startup and commissioning times. Visibility into the system enables insightful diagnostics and improved troubleshooting for maintenance activities. Precise optimization controls through EEVs allow retailers to take advantage of low condensing operation. All of these benefits add up to significant energy consumption reductions and streamlined operations that translate into ongoing savings.

John Wallace has been active in the design and development of electronic control systems for over 20 years holding