by Steve Spielmann

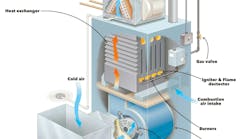

There are two types of tubular boilers: firetube and watertube. In the watertube boiler, water is carried in the tubes and heated until it becomes high pressure steam. In most areas, watertube boiler plants must have licensed stationary engineers on hand at all times, and maintenance is usually performed by in-house personnel.

In the firetube boiler, water surrounds the tubes and hot gasses travel through them. This results in soot and scale deposits accumulating within the tubes. No matter what fuel is used, the tubes need to be cleaned regularly. If they aren’t, boiler efficiency is sacrificed and fuel wasted. Soot actually has five times the insulating capacity of asbestos.

For example, a 18-in. coating of soot can accumulate in a firetube boiler in just two weeks, resulting in a heat loss of 47% and an increase in fuel consumption of 812%. As the layer of soot builds up, the stack temperature rises. For every 40F rise in stack temperature, boiler efficiency is reduced by 1%. That’s a pretty good argument for regular tube cleaning.

Some Firetube Cleaning History

Over the years, several methods have been developed for cleaning boiler firetubes. Twenty-plus years ago, one popular method was the use of soot blowers: steel tubes fitted with blowing nozzles that were mounted on the tube sheet of the boiler. They were mounted in a way that allowed nozzles to be maneuvered to blow steam or air through each tube.

Soot was simply blown out through the smoke stack and into the atmosphere — a practice that is frowned upon today. Today, soot blowers are used mainly in large power utility boilers where the smoke stacks are equipped with scrubbers and other environmental devices.

Another tube cleaning method practiced by some boiler technicians was washing out the tubes using a fire hose. One can imagine the mess this left behind. Yes, the tubes were cleaned, but the boiler room was left with a layer of black mud on the floor. It took longer to clean the floor than the tubes.

In most cases, tube cleaning was strictly a manual operation requiring a great deal of time, labor, mess, and inconvenience. Brushes fastened to long, heavy metal rods were manually pushed and pulled through the soot laden boiler tubes, resulting in clouds of soot filling the air and settling on every surface in the room.

The backbreaking effort went on for hours, followed by the immense task of individually vacuuming each tube and cleaning up the boiler room.

Now for Watertubes

Most watertube boilers have tubes in a more or less vertical position. Though some have straight tubes, which can be cleaned as described above, most watertube boiler tubes have bends in them, making them more difficult to clean.

In addition, where firetube boilers commonly have only soot and ash to be removed, watertubes commonly have scale deposits that adhere stubbornly to the tubes.

The amount and nature of the scale are determined by the water quality and the effectiveness of water treatment. Scale is formed when water is heated and suspended solids in the water precipitate out onto the heating surfaces. A well-managed water treatment program is essential to minimizing scale deposits.

Early watertube cleaning devices used cylindrical air motors fitted with complicated cutter heads fastened to the end of a heavy compressed air hose. The entire motor/cutter assembly was then fed manually through the tubes and cleaning was performed dry, followed by a flushing with a water hose. Each air motor was good for only a narrow range of tube sizes, so if the user had many tube sizes to clean, he had to have multiple air motors, which drove up the cost.

Good News: There are Better Ways

Over the years, great strides have been made in tube-cleaning technology. Equipment is now available that enables one operator to perform two tasks at once in a fraction of the time.

For firetubes with soot deposits, there are machines that mechanically drive brushes or scrapers through the tubes, requiring almost no human effort. These machines are, in turn, connected to powerful vacuums that draw the loosened soot from the tubes simultaneously, leaving the tubes, boiler room, and operator completely clean.

Some firetube boilers develop scale deposits. This is particularly true with waste heat boilers and boilers fired on lesser quality fuels. Some of the worst waste heat boilers are found at hospitals where medical waste is burned in incinerators and a boiler is used to capture the subsequent heat generated. In many cases, a straight brushing action isn’t sufficient, and rotary equipment must be used.

Manually fed rotary systems are available that incorporate simultaneous vacuuming as well. Many of these systems were based on designs originally intended for condenser and chiller tube cleaning, and they work extremely well on scaled boiler tubes.

There is also equipment now available with more powerful air motors that drive flexible shafts fitted with a wide variety of cleaning tools. The flexible shaft is sheathed in a water-tight casing that transports water right to the cleaning tool. This allows tubes to be cleaned and flushed in a single operation.

About Chemical Cleaning

Chemical cleaning has been used on boilers for many years and is still periodically needed to clean the waterside of firetube boilers. Chemicals effectively remove calcium carbonate and other scales that adhere to heating surfaces. However, this method should only be performed when deemed necessary by technicians trained and equipped to do the work safely. Chemical cleaning presents the following challenges:

- Cost - chemicals are expensive

- Safety - chemicals present potential danger to personnel and equipment

- Environmental concerns - what if there is a spill?

- Time - chemical cleaning can add up to a week to an outage.

Considering these challenges, it’s important to know when a boiler needs chemical cleaning. It’s worse to chemically clean a boiler that doesn’t need it than to not clean one that does. Improving water chemistry and start-up practices can extend the time between cleanings.

Efficiency Testing

Every boiler maintenance program should include regular efficiency testing because such tests reveal trends that indicate it’s time to clean the boiler. For example, an increase in stack temperature frequently signals soot or scale build up. An electronic combustion efficiency tester should be considered standard for the maintenance program. They are absolutely essential for tuning the burner properly. Many models of testers are available today with capabilities to measure and/or calculate net stack temperature, oxygen, carbon monoxide, carbon dioxide, nitrous oxide, excess air, and other values.

Regular boiler maintenance that includes thorough cleaning of the boiler tubes will result in lower operating costs and fuel consumption, greater efficiency and longer heating system life.

Steve Spielmann is the customer service and technical manager at Goodway Technologies Corp., Stamford, CT. He has been in the HVAC maintenance business for more than 27 years. He can be reached via e-mail at: [email protected].