While the use of Ultraviolet-C (UV-C) light in today’s modern heating, ventilation and air conditioning (HVAC) equipment is now commonplace, it wasn’t always that way. In fact, now known for delivering upwards of 25% energy savings, boosting airflow and extending HVAC equipment life, UV-C technology got its start by providing cleaner, healthier air.

During the mid-1990s, UV-C became popular in commercial air handling equipment to help mitigate the indoor air quality (IAQ) issues dominating the concerns at that time. 1,2,3

During this period, IAQ investigations discovered that the dark, cool and moist environment of an air handling unit (AHU) offered a perfect breeding ground for unhealthfulorganisms — primarily fungi and bacteria — and that these organisms and their by-products could be efficiently spread throughout occupied spaces. Researchers established causal links between the bacteria and allergic rhinitis, asthma, humidifier fever, and similar relationships with hypersensitivity Pneumonitis and their toxins (endotoxins and mycotoxins) as causing a variety of toxic effects, irritation and odors. Hospitals, with immunocompromised patients, were of even greater concern.4

Mold, the most common allergen, easily grew in the dark and moist environments of air conditioning systems, primarily on cooling coils, and was found to proliferate year-round. Continuous exposure to mold and mold products can initiate the release of histamines, inflame mucus membranes and often lead to itchy eyes, scratchy throats, congestion, chronic sinusitis, headaches, breathing difficulties, and were also thought to contribute to asthma attacks and other complications — all of these were reported symptoms of that period.5

Solving Sick Building Syndrome

IAQ experts came to realize that biological contaminants (bioaerosols) were a major contributor to Sick Building Syndrome and Building-Related Illness. Hundreds of buildings with major IAQ issues turned to UV-C lamp installations as a primary solution. Fixturing was installed downstream of the cooling coil to kill microbial contaminants as found on the coils, in drain pans and on surrounding components. The 254 UV-C germicidal wavelength reflects exceptionally well throughout the coil to kill and degrade the problematic microbes.6

One example was the public utility building housing the Public Service Company of Oklahoma, Tulsa (PSO). At this unit of American Electric Power, both employee complaints and mold proliferation in the air handling units were high. When employee complaints and/or visible mold reached certain levels, the building engineer applied biocidal agents to the all system cooling coils and their plenums, which was at least four times per year. This costly and labor intensive procedure was not solving the mold proliferation and subsequent allergic reactions, so in 1996, the engineer installed the first set of UV-C lights in his worst unit. Both the mold and complaints vanished and stayed that way for the rest of the year.7

Based on this experience, the PSO building engineer equipped two more air handling units with UV-C. They performed so well that the results got the attention of the University of Tulsa, which sent a team of IAQ investigators to research the startling turnaround. Results were so good that a research paper was drafted, which was published in Applied and Environmental Microbiology.4 Within a short time, all of the PSO building’s air handlers were equipped with UV-C and continue to work well to this day. Since that early install, however, much more was being learned about the diverse benefits of UV-C on cooling coils.

UV-C Boosts HVAC System Efficiency, Cuts Energy Use

After the first UV-C unit install in 1996, the PSO building engineer discovered that the AHU was generating too much airflow, which meant he needed to return the unit’s fan and motor sheaves (pulley assemblies) to their original settings in order to reduce fan RPM. Additionally, he noticed that after all the air handlers had been equipped with UV and the fans returned to original RPM, the building’s standby chiller stopped running at full capacity – something that hadn’t happened in more than 10 years. He shut down the standby chiller and later estimated that, together with the fan RPM reductions, the utility was saving at least 20% in energy use by simply incorporating UV-C.7

Together with the fan RPM reductions, the utility was saving

at least 20% in energy use by simply incorporating UV-C.

Over the next few years, continuing interviews with other UV-C users yielded even more reports of increased airflow, especially on systems where fan rpm had been increased from original specifications. This caught the attention of a Carrier distributor in California who had both poor IAQ and a poorly performing, constant volume DX system. They installed UV-C in 1997 to test it for themselves.8

To see if there would be an enthalpy change at the coil, the investigators used the equation:

— BTUs = CFM x 4.5 x (h1 - h2 ) — as found in Carrier literature.

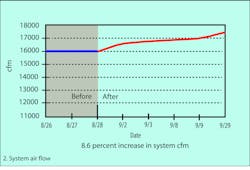

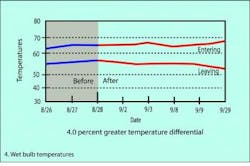

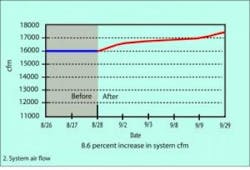

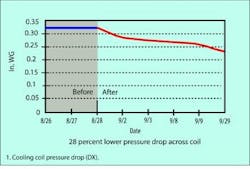

They first measured airflow and air entering and leaving wet bulb temperatures (h) for three days to establish a baseline. Then the distributor’s own personnel installed UV-C downstream of the coil and ran the lamps 24/7 for one month in August/September. Coil pressure drop fell by 28% and airflow increased from 15,920 to 17,160 CFM. The "before" wet bulb EATs and LATs were 62.5 and 52.5 and the "after" readings were 66.5 and 52.5 respectively. This yielded a 4F increase in temperature differential, even at the new, and higher, airflow. (See Figures 1 and 3)

Populating the equation with the collected numbers shows that the distributor’s test unit went from 464,272 BTUs of heat removed on Aug. 28, 1997 to 733,590 BTUs of heat removed on Sept.29, 1997 — or, a performance gain of more than 50%. The increased capacity helped achieve the building’s target space temperature for the first time in a long time, even though it was one of the hottest days of the year.

This particular test was significant as it is one of a very few DX systems equipped with UV that also involved highly skilled investigators who independently gathered the data. For the millions of DX users across the U.S., these data provide assurance of colder off-coil air temperatures, improved space dehumidification and therefore less run time. In other words, in addition to better IAQ, DX users can also look forward to a more comfortable working environment while using less energy to achieve it.

Another application at the Norman Regional Health Center in Oklahoma involved a chilled-water unit serving several nursing stations and corridors, which had near non-existent airflow such that space temperature was not being met and the floor went negative in relation to the adjoining patient rooms. The fan had been sped-up an unknown number of years earlier, but even that makeshift solution was eventually defeated by what was shown to be a clogged coil. A decision was made to replace the coil and contractors were called to bid the project. However, due to poor AHU access, the bidding contractors said they would not be able to remove the old coil. Not being able to live with the condition, the health center decided to try UV-C.9

Restoring Cooling Capacity to Yield Cleaner, Healthier Air

Thirty-nine days following the installation of the UV-C system, the health center recorded a significant drop in coil pressure from 3.07-in. to 0.77-in. At around this point, the building engineer was receiving complaints of nurses being too cold, papers blowing off desks and a loud noise. The noise turned out to be the sped-up fan. Because the building engineer had kept the original sheaves, he was able to re-sheave the fan back to its original rpm. Everything turned out so well that he no longer needed the chilled water valve open to 100%, to make temperature.10

While it's well established that UV-C kills microorganisms, many are not aware of its ability to photo-disassociate and degrade organic debris, which leads to its remarkable coil cleaning benefits. It's now amply proven that UV-C eats away accumulated organic materials and biofilm growth in cooling coils to significantly improve airflow and heat-transfer efficiency levels, which not only reduce energy use, but also decrease system maintenance and their associated costs while providing cleaner, healthier air.11

While it's well established that UV-C kills microorganisms,

many are not aware of its ability to photo-disassociate

and degrade organic debris, which leads

to its remarkable coil cleaning benefits.

Originally, the goal for UV-C was to eliminate the proliferation of mold and Gram negative bacteria on cooling coils and in drain pans to mitigate the occupant complaints associated with this common contaminant source in A/C equipment. However, in addition to improving IAQ, today, the hidden value of UV-C is its ability to restore cooling capacity, reduce maintenance and to increase the potential of energy savings.12

This trifecta of boosting capacity, lowering maintenance, and saving energy is driving more than nine-of-every-ten UV-C installations today. All of these system-enhancing efficiencies of UV-C technology are discussed in greater depth as found in ASHRAE’s 2011 Handbook of HVAC Applications, Chapter 60.8, a link to which may be found here: https://www.ashrae.org/resources--publications/Description-of-the-2011-ASHRAE-Handbook-HVAC-Applications.13

References

1 Scheir, R., & Fencl, F.B. (1996, February). Using UVC technology to enhance IAQ. Heating/Piping/AirConditioning, pp. 109–123.

2 ACR News, June 10, 1996. Shining the light on ductwork mold may cure building illness.

3 ACR News, August 11, 1997. Ductwork gets a UV-Rx, curing mold growth problems

4 Levetin, E., Shaughnessy, R., Rogers, C.A., & Scheir, R. (2001). Effectiveness of germicidal UV radiation for reducing fungal contamination within air handling units. Applied and Environmental Microbiology, 67, 3712-3715.

5 ACR News, July 10, 2000. UV Technology Sheds Light on IAQ Problems

6 Menzies, D., Popa, J., Hanley, J.A., Rand, T., & Milton, D.K. (2003). Effect of ultraviolet germicidal lights installed in office ventilation systems on workers’ health and well being: Double-blind multiple crossover trial. Lancet, 363, 1785-1792

7 Contracting Business, November, 1997, p.105; Service Clinic: Coil Cleaning: Myths and Misrepresentation.

8 HPAC Engineering, October 1998, p. 11: UVC Lights Enhance IAQ, Reduce AHU Operating Costs.

9 Kowalski, W. (2009). Ultraviolet germicidal irradiation handbook: UVGI for air and surface disinfection. Berlin: Springer-Verlag.

10 Montgomery, R.D., & Baker, R. (2006, November). Study verifies coil cleaning saves energy. ASHRAE Journal, pp. 34-36.

11 Witham, D. 2005. Ultraviolet—A superior tool for HVAC maintenance. IUVA Congress, Tokyo.

12 Federal Standards for Public Buildings Service, P 100

13 ASHRAE. (2011). ASHRAE handbook—HVAC applications (ch. 60.8). Atlanta: ASHRAE.

The president of UV Resources, Forrest Fencl is the holder or co-holder of 15 patents and the author or co-author of numerous papers and articles and several ASHRAE Handbook chapters related to ultraviolet air and surface treatment. He is a Life member of ASHRAE, an ASHRAE Fellow, formerly an ASHRAE Distinguished Lecturer, and a member of the International Ultraviolet Association(IUVA) and the Illuminating Engineering Society (IESNA).