How to Calculate Water System BTU Measurements

In this column, the subject of HVAC Air System BTU measurement is frequently referred to as the foundational calculation for system efficiency. While it may surprise some of you "air heads," there are regions of the country where homes and buildings are heated with water. Let’s take a look at how "wet heads" calculate water system BTU.

The Cost of Heating Water

The first snowstorm of the year arrived early in Ohio. Just out of bed before 5 am on that day, I was greeted by the warm tile floors in our master bathroom. My high-flow showerhead warmed me even more. Efficiency is not the priority in our bathroom, comfort is!

Leaning against the shower wall, my mind began to calculate other areas of efficiency in our home that offset the comfort luxuries of warm floors and the showerhead. I started calculating flow rate and temperature differences, and before I washed my hair, I quickly calculated the low-efficiency cost of my morning comfort at less than a dollar. I was OK with that.

This will be a brief introduction to water system BTU measurement. If you would like more information, I can send you a more detailed procedure, just email me at the address found at the end of the article.

The Formula

Math is the key to understanding how BTUs move through a system. The simple formula for water is:

System Delivered BTU = 500 x GPM x System Water Temperature Change

Let’s take a look at the formula to see what each piece of it means to help you understand it better.

- The BTU multiplier in the formula is 500. Because BTUs are measured per hour, the 500 comes from one gallon of water that weighs 8.33 pounds, times 60 minutes in one hour. (8.33 pounds X 60 minutes = 500)

- The second piece of the formula and sometimes the hardest to identify is the flow rate in GPM, or the system gallons per minute. We’ll talk more about this subject in a bit.

- Finally, you’ll need the system temperature change. Notice we’re talking about the system temperature change, not the equipment temperature change. Temperature change is the effect of the BTUs transferred from the system, hopefully into the conditioned space. So if you’ll measure the temperature of the water leaving the heat exchanger and subtract the temperature of the water returning from the system, you’ll find the system temperature change.

Calculate Pump Pressure and Plotting GPM

For the purposes of this article and since we will only be considering the basics, let’s take a look at calculating pump pressure and plotting GPM in a residential hydronic heating system. We could discuss far more accurate methods, but this is a starting point; call it an initial performance test for beginners.

Most pump curves are easily found online. Simply search for the words, "pump curve," with the model number and manufacturer's name.Since you don’t have to deal with duct leakage issues, you may assume the pump GPM is the system GPM. Two bits of information are needed to estimate pump GPM. The first item is the pump curve. When a pump is built, each manufacturer publishes the pump’s performance curve. You must have the exact manufacturer’s curve matching the installed pump with the correct impeller size, RPM, and exact model number or your BTU test can be off by more than 50%.

Like a fan curve, this table graphically represents the performance of the pump under certain field conditions. You can use field data to plot the pump GPM.

Ideally, pump pressure is measured using pressure gauges or a circuit setter. For introductory purposes, we’re going to calculate pump pressure using a time-tested and approximate residential method.

When performing the test, make sure that all zone valves are open and calling for heat. The system performance test will be inaccurate if one or more of the zones are closed.

To calculate pump pressure on a simple residential system, use the following formula: Pump Pressure in Feet of Head = Feet of Pipe x 1.5 x .04.

1. First, to find the Feet of the Pipe, measure the total linear feet of supply and return pipe to and from the farthest heating device in the house. The 1.5 in the formula is a factor to include the pipe resistance to flow (pressure) and the pressure drop of the system components (coils, baseboards, radiators, and excess fittings). The .04 represents the typical pipe friction rate per 100 feet of pipe.

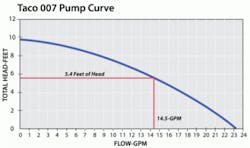

- Example: Say a home has 90 feet of pipe in a hydronic heating system. The formula would be 90 feet x 1.5 x .04 = 5.4 Feet of Head.

2. Once you have calculated the pump pressure, you can use the pump curve to plot the pump GPM.

- First, mark the calculated pump pressure on the left side of the pump curve where the feet of head pressure is found.

- Second, plot a straight line horizontally to the right until the line intersects the rounded pump curve line.

- Third, plot straight down to the bottom of the table to find the GPM the pump is moving. In this case, using one of the most common residential pump curves, a Taco 007, you identify the pump GPM at 14.5.

Now you have found the pump GPM, you are one step closer to finding the system-delivered BTU.

System Temperature Measurement

To be completely accurate, a submersion thermometer should be inserted into the water. However, most residential systems probably don’t have Pressure/Temperature plugs to gain access to the water temperature, so you can measure the temperatures on the surface of the pipe, wrapped with insulation or by using a clamp-on thermometer specially made for pipe temperature measurement.

Since you are checking the system performance, not the equipment performance, measure the temperature of the water at least 10 pipe diameters downstream from the pump or heat exchanger where the water is leaving the equipment. Read and record the temperature down to the closest 1/10th of a degree.

Measure the returning water temperature by measuring the temperature of the pipe at least 10 pipe diameters before the pipe returns to the equipment. Be sure not to measure directly over the equipment or too close to the flue so you don’t pick up additional heat in your water temperature measurement.

Subtract the supply water temperature from the return water temperature to find the system temperature change.

Calculate System Delivered BTU

To find the system-delivered BTU, multiply the BTU multiplier of 500 x the estimated Pump GPM x the System Temperature Change.

Example: Say you calculate the pump pressure at 5.4 feet of head. Using the pump curve you plot and find the Taco 007 Pump is moving 5.4 GPM. Then you measure the system temperatures and find the discharge temperature to be 168.2F and the return temperature to be 152.4F. You subtract to find the system temperature change of 15.8F. Now that you have all the facts, apply the hydronic BTU formula: 500 x 5.4 Gallons X 15.8° = 42,660 BTU.

The real question: is the system BTU delivery close to the equipment performance specifications? Or is it a new 80,000 BTU output boiler hacked into a 40-year-old mucked-up piping system? Perhaps your customer would like you to prescribe some additional system improvements.

That’s all you need to do to complete the initial residential hydronic system BTU calculation. Remember, this is just an initial test. There are far more definitive test procedures required to increase accuracy in calculating system delivered BTU; but this is a great start.

Unfortunately, it’s not uncommon to find the hydronic system performance well below 60% of the equipment’s rated output. It’s probably not a good idea to promise your customers that their hydronic heating system is perfect until you measure its performance. Assuming a system is performing at the published equipment rated capacity is probably not a good idea.

So, how well was the last water system you worked on performing? Or, how badly was it performing? If you can’t honestly answer that question, you might want to measure next time.

Rob “Doc” Falke is president of National Comfort Institute a training company specializing in measuring, rating, improving, and verifying HVAC system performance. If you're an HVAC contractor or technician interested in a procedure to measure the performance of a hydronic heating system, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at nationalcomfortinstitute.com for free information, technical articles, and downloads.

About the Author

Rob 'Doc' Falke

President

Rob “Doc” Falke serves the industry as president of National Comfort Institute an HVAC-based training company and membership organization. If you're an HVAC contractor or technician interested in a building pressure measurement procedure, contact Doc at [email protected] or call him at 800-633-7058. Go to NCI’s website at NationalComfortInstitute.com for free information, articles and downloads.