Latest from Service

EDITOR'S NOTE: This article was updated to include a tutorial video.

Here's a common scenario. You go on a service call, put your gauges on a condensing unit, and find that the suction pressure is low. What do you do?

In too many cases, the answer is "add refrigerant." But doesn't it seem like a good idea to confirm that low refrigerant is the problem before you start adding refrigerant? That's why checking superheat and subcooling is so important.

Let's go back to the beginning. You go on a service call and find low suction pressure. However, this time you consider the three main causes of low suction pressure and check superheat and subcooling to make the correct diagnosis.

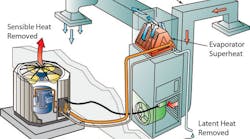

CAUSE #1: Insufficient heat getting to the evaporator.

This can be caused by low airflow (e.g., dirty filter, slipping belt, undersized or restricted ductwork, dust and dirt buildup on blower wheel) or a dirty or plugged evaporator coil.

Checking superheat will indicate if the low suction is caused by insufficient heat getting to the evaporator.

To check superheat:

1. Attach a thermometer designed to take pipe temperature to the suction line. Don't use an infrared thermometer for this task.

2. Then take the suction pressure and convert it to temperature on a temperature/pressure chart. Subtract the two numbers to get superheat.

For example, 68 psi suction pressure on a R-22 system converts to 40°F. Let's say the suction line temperature is 50°F. Subtracting the two numbers gives us 10°F of superheat. Superheat for most systems should be approximately 10F measured at the evaporator; 20°F to 25°F near the compressor.

If the suction pressure is 45 psi, (which converts to 22°F) and the suction temp is 32°F, the system still has 10°F of superheat. The fact that these readings are normal indicates the low suction pressure is not caused by low refrigerant, but insufficient heat getting to the evaporator.

CAUSE #2: Defective, plugged, or undersized metering device.

Let's say a system has 45 psi suction pressure (converts to 22°F) and 68°F suction line temperature, the superheat is 46°F (68 minus 22). This indicates low refrigerant in the evaporator. However, before adding refrigerant, check the subcooling to be sure the problem isn't caused by a defective, plugged, or undersized metering device.

While superheat indicates how much refrigerant is in the evaporator (high superheat indicates not enough, low superheat indicates too much), subcooling gives an indication of how much refrigerant is in the condenser.

Subcooling on systems that use a thermostatic expansion valve (TXV) should be approximately 10°F to 18°F. Higher subcooling indicates excess refrigerant backing up in the condenser. On TXV systems with high superheat, be sure to check the subcooling as refrigerant is added. If the superheat doesn't change, and the subcooling increases, the problem is with the metering device. In the case of a TXV, it's likely that the powerhead needs to be replaced.

To check subcooling, attach a thermometer to the liquid line near the condenser. Take the head pressure and convert it to temperature on a temperature/pressure chart. Subtract the two numbers to get the subcooling.

For example, 275 psi head pressure on an R-22 system converts to 124°F. The liquid line temperature is 88°F. Subtracting the two numbers gives 36°F. High superheat and high subcooling indicates a problem with the metering device.

Keep in mind that subcooling won't increase on systems with a liquid line receiver, as extra liquid will fill the receiver instead of backing up in the condenser. Receivers are rare on air conditioning systems but very common on small refrigeration systems such as walk-in coolers and freezers. If a system with a receiver has high superheat and the liquid line sight glass is full of liquid (no bubbles), check the metering device. If the sight glass has bubbles, the system could be low on refrigerant, or the liquid line filter/dryer could be plugged. Your clue here is that a noticeable temperature drop across a liquid line filter/dryer indicates it's plugged.

CAUSE #3: Low refrigerant.

Yes, it's true! There are indeed some cases where low suction pressure is going to be caused by low refrigerant. If the superheat is high and the subcooling is low, the refrigerant charge is probably low. Just keep in mind two things here: first, find and fix the leak. Second, monitor both superheat and subcooling as you add the refrigerant, to prevent overcharging.

Skip Egner is a technician with CS Service Experts, Ft. Myers, FL. He has been in the HVAC industry for 30 years, and in 2006 won the North American Technician Excellence (NATE) Certified Technician Competition at HVAC Comfortech. He can be reached at 239/768-2665.

As a "Top Tech," here's what Egner says about NATE: "A service technician needs to have a high mechanical aptitude and the ability to understand complex mechanical systems. NATE certification is important to let the customer know that the technician working on their system has been trained and tested, and is competent to solve the problem."

EXTRA: SEE THIS VIDEO FOR ADDITIONAL TIPS BY AC SERVICE TECH